Dec 11, 2021

Double Body Torsion Springs Overview

Here's another look at double body torsion springs. We've previously blogged on this topic and you can check that out here! In this post we're providing more information regarding the production of these springs and the importance of a CNC coiler (also referred to as a CNC machine) in its making. These springs definitely require a manufacturer with top talent as well as the latest in CNC technology.Production

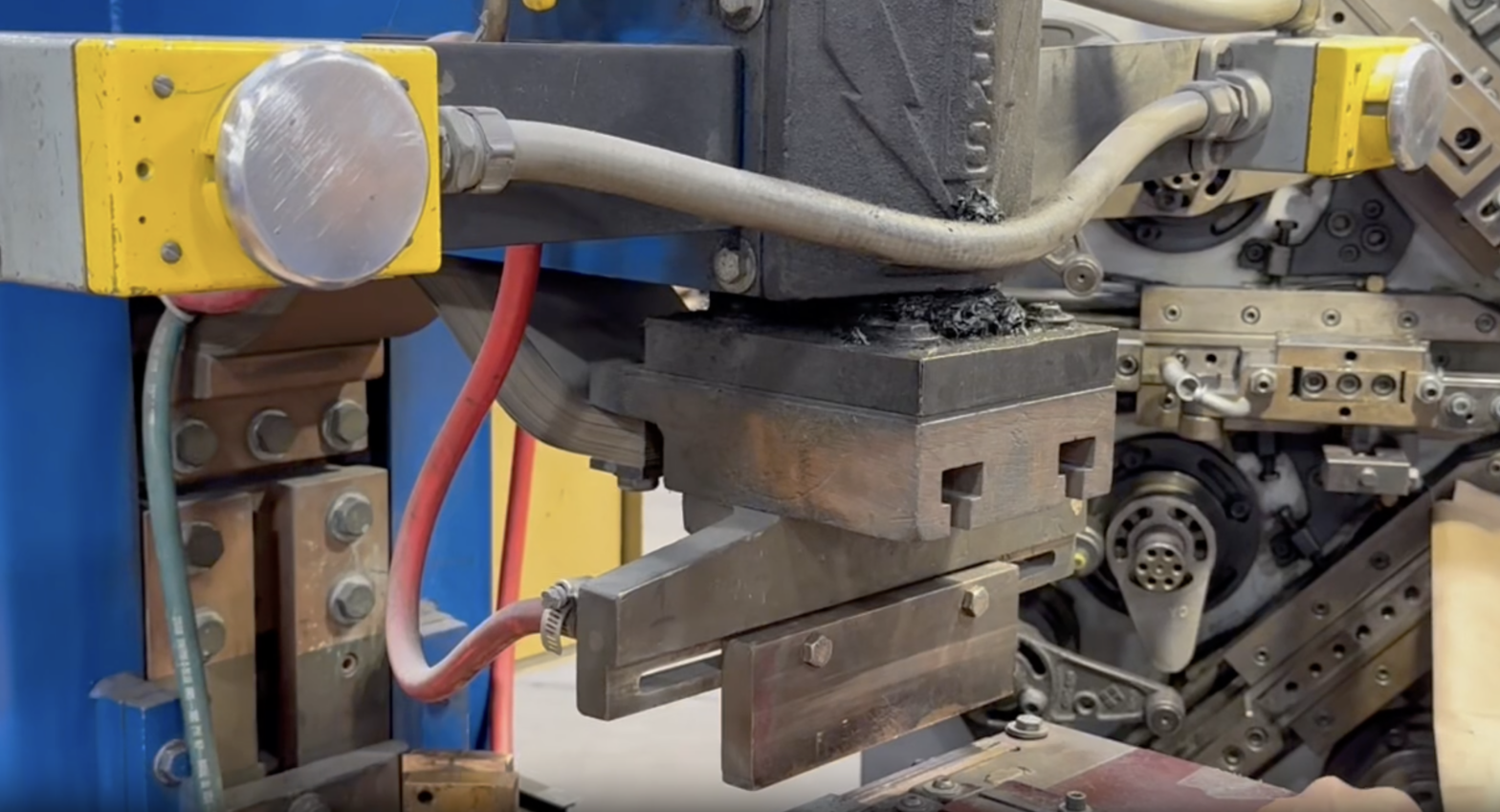

Click the link to the video above to see our production technique. You can also view the video on our Facebook page. Please like and share, your feedback is welcome! We use CNC technology in the production of our double body torsion springs. Now you may be wondering, what exactly is CNC technology and a CNC machine? CNC machines are machines that are automated by a computer. In fact, CNC stands for computer numerical control! With this technology, these machines are programmed to do a task rather than rely on human operation. In our case, we utilize a CNC coiler to efficiently produce springs that are consistent in quality. Making this unique part without a CNC machine entails long run times along with the use of a manual hand winder and multiple secondary setups. A CNC coiler may require a longer set-up time, averaging roughly 8-12 hours, however this time is well invested as the CNC machine eliminates many of the manual processes otherwise required. By using a CNC coiler machine we are able to quickly and accurately fulfill your spring order; this machine aids in the repeatability of our production and is definitely a key component in being a top spring manufacturer. With CNC technology we are able to produce double body torsion springs for many industries – from automotive to hardware, we can produce the right spring for you, on time and within budget. Contact us at 281-391-1888 for any questions or more info!GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC