Types of Spring Assemblies

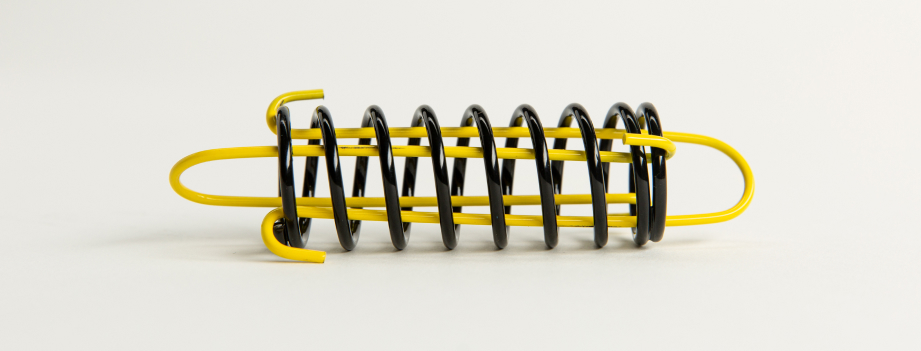

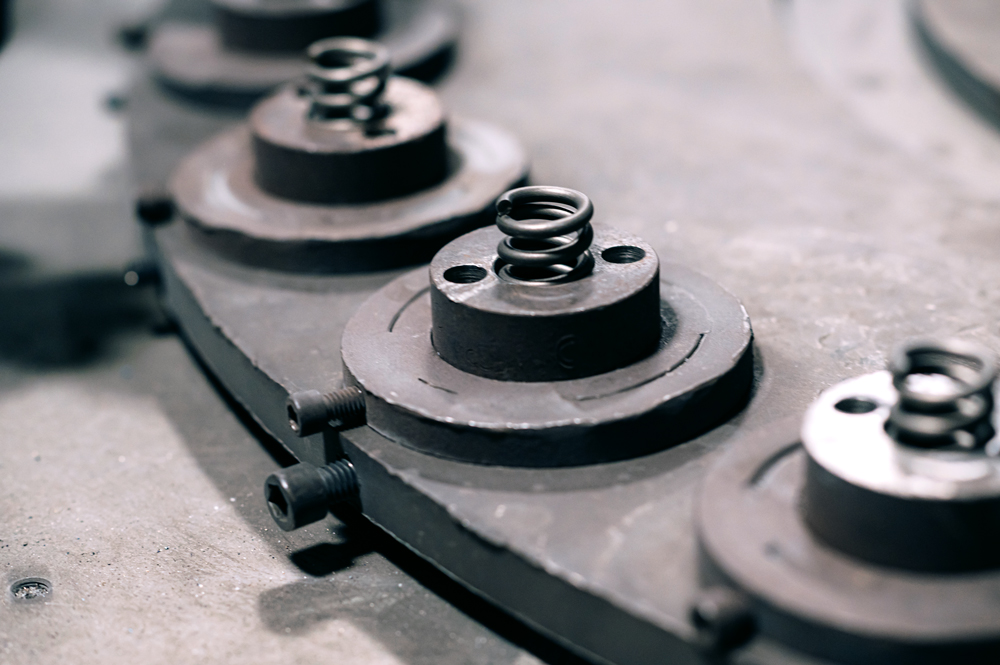

Compression Spring Assemblies: Designed to compress underload, store mechanical energy, and provide a return force when the load is removed. Used in machinery, industrial equipment, and consumer products like pens, and medical devices.

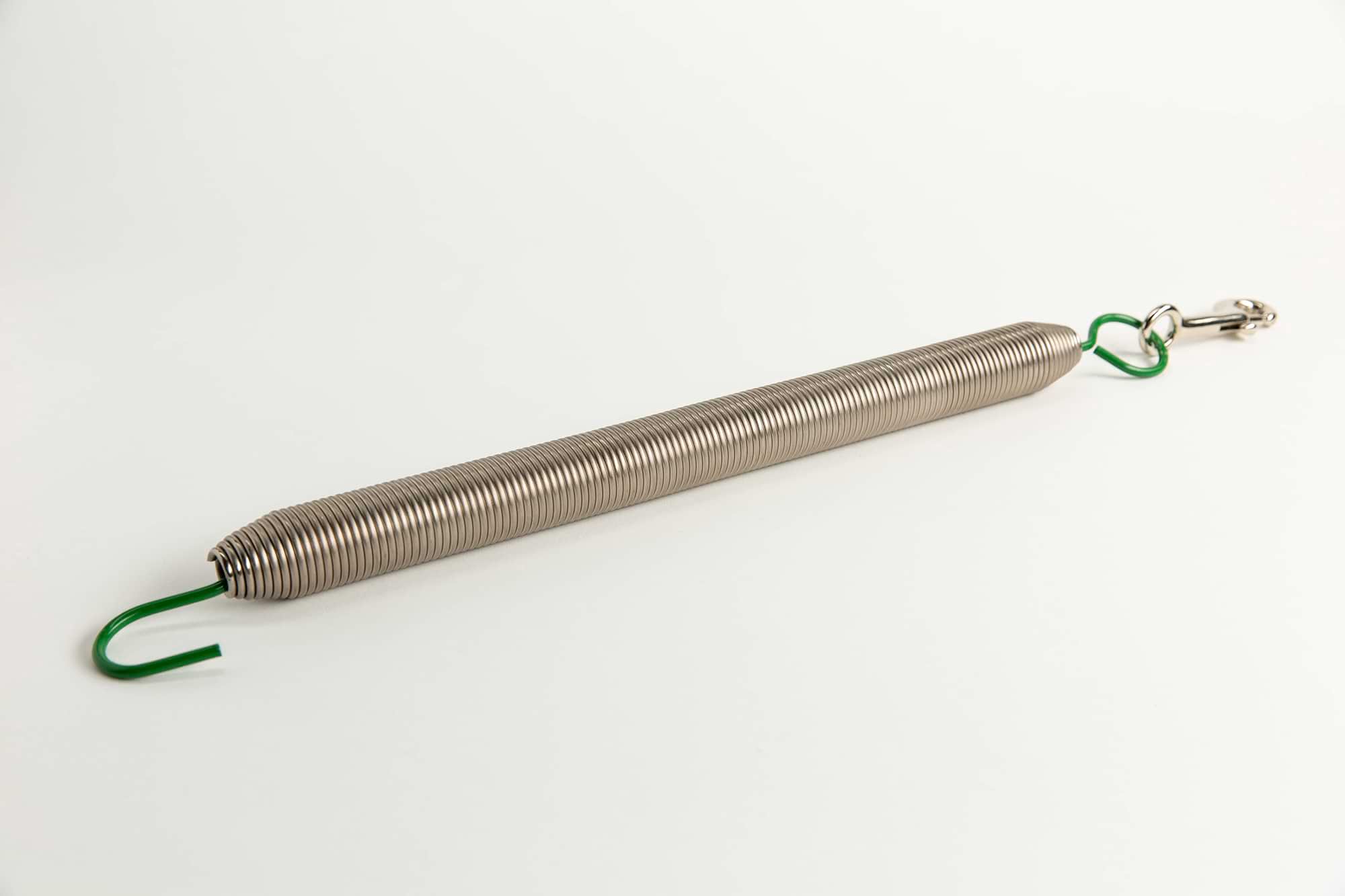

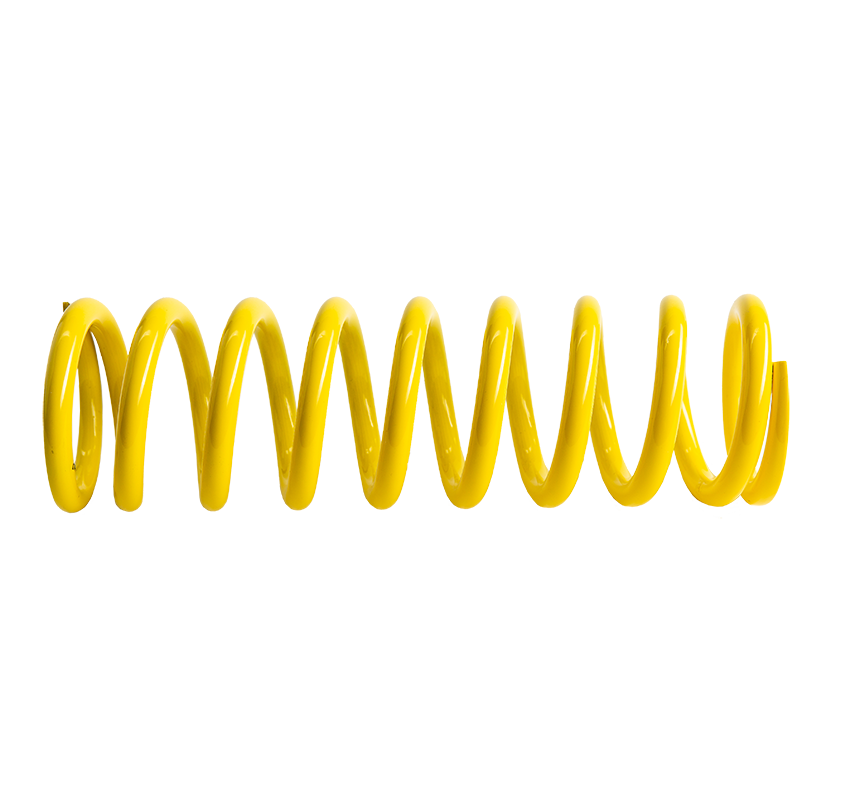

Extension Spring Assemblies: Designed to extend under load, store energy, and provide a pulling force when the load is removed. Commonly found in garage door mechanisms, trampolines, and various automotive and industrial applications.

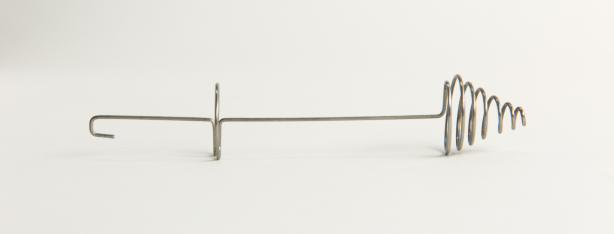

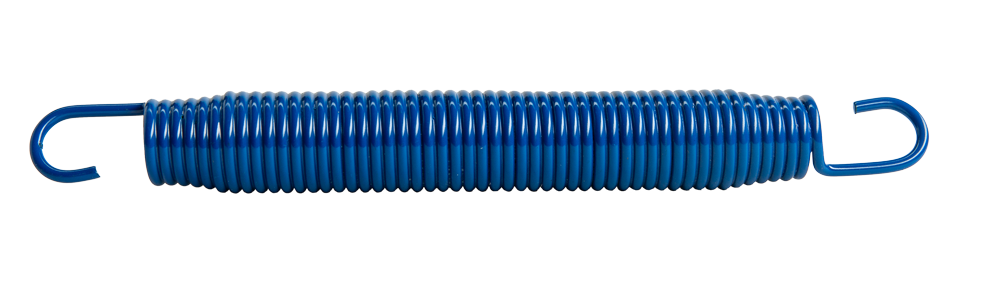

Torsion Spring Assemblies: Designed to twist under load, store energy in a rotational manner, and provide torque or rotational force. Used in clothespins, mousetraps, window shades, and hinges.

Applications of Spring Assemblies

Industrial Machinery: Springs absorb shocks and vibrations, protecting machinery components and enhancing durability. Used to maintain consistent force in presses, stamping machines, and assembly lines.

Consumer Products: Springs are used in everyday items like retractable pens, watches, and door handles to provide motion and force. They are also found in appliances like washing machines, where they help in balancing and damping vibrations.

Medical Devices: Springs are used in medical instruments for precise control and movement. They also provide necessary flexibility and support in prosthetic limbs.

Construction and Infrastructure: Used in bridges and buildings to absorb seismic shocks and reduce structural damage during earthquakes. They also provide necessary counterbalance and smooth operation in elevator mechanisms.

view product overview

Order Custom Springs

The basic information needed by Katy Spring is material, wire size, free length, number of coils, travel, diameter, end types, finish, works over, works in, and maximum solid height.

- request a quote

- Questions? (281) 391-1888

Leaders in custom springs

Regardless of the custom spring type, quantity, or size, the team at Katy Spring is ready and able to help deliver precision and quality quickly. Our smooth processes and extensive quality checks mean you’ll enjoy the approach just as much as the product. We’ve love to earn your business. Reach out today.

Katy Spring

Partners in Precision

Shape & Sizes

No matter the shape, size, or functionality, Katy Spring can help design a custom spring to fulfill your requirements.

Body Types

Cylindrical

Conical

Barrel

Hooked

Variable Pitch

Common Spring Materials

Carbon Steel

Alloy Steel

Stainless Steel

Nickel Alloys

Copper Alloys

Brass

product gallery

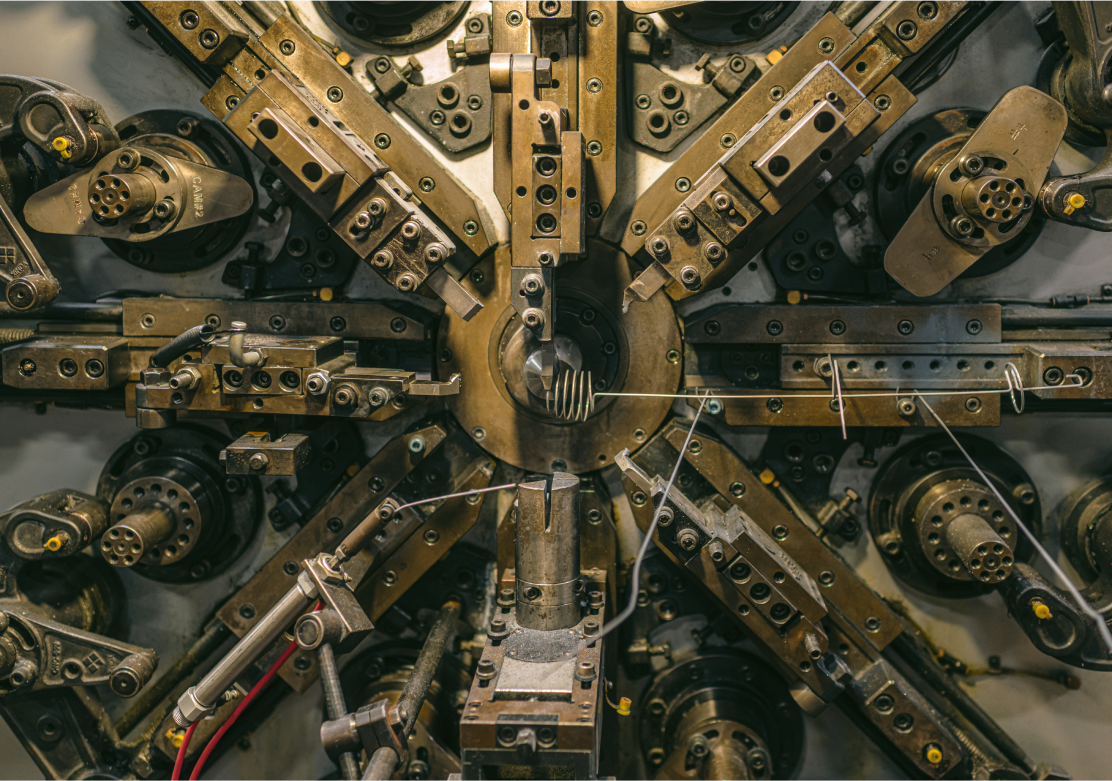

katy spring has manufactured over 10M springs made since 1999

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

What our customers say

“ Definitively I will Katy Spring in our preferred list of spring supplier, excellence and fast quoting service.”

-

Héctor G.

Precision Tools

“ Spot on. Let me get in touch with our customer to see how they want to proceed. Thank you for the quick...”

-

Joe H.

Oil Rig Design Engineer

“ I have at least three more good volume items to quote. I will get those over to you. Your pricing has been...”

-

Marsha R

Engineered Valves

Need a quote? It’s quick and easy, start here:

ordering custom spring Assemblies

Your One Stop Shop

Our team of engineers and experienced spring manufacturing pros offer “one stop shop” solutions and are available to consult on your spring assembly needs, including the possibility of turnkey assembly in addition to spring manufacturing. We design and build the tools and parts you need, and offer the following services:

Mechanical Assembly Applications

Let Katy Spring help source multiple parts and combine components with several origins to alleviate production challenges. We strive to provide the lowest possible costs and the highest possible quality for the various sectors we serve:

- Machining

- Stamping

- Coiling

- Forming

- Brazing

- Drilling

- EDM Work

- Heat treating

- Swaging

- Coiling

- Grinding

- Welding

- Tapping

- Aeropace

- Automotive

- Fuel Dispensing

- Industrial

- Medical Devices

- Military

Types of Spring Assemblies

We offer many variations of springs for your project. Select one to learn more:

other springs we manufacture:

Compression Springs

A compression spring is a type of mechanical spring designed to resist compressive forces. When subjected to a load, it compresses and stores mechanical energy. Upon the release of the load, the spring returns to its original shape, releasing the stored energy.

- conical

- -

- concave

- -

- convex

Extension Springs

An extension spring is a type of helical (coiled) spring designed to store energy and resist a pulling force. When extended, it exerts a return force to pull the components back together. These springs are used in various applications requiring tension, resistance, and the ability to return to a pre-determined position after being stretched.

Flat Springs

A flat spring is a type of spring made from a flat, thin piece of metal or composite material. Unlike traditional coiled springs, flat springs are designed in a variety of shapes and sizes to store and release energy through bending or flexing. They are used in applications requiring precise force, flexibility, and a compact design.

- Nickel-silver

- -

- Beryllium-copper

- -

- Stainless steel

Torsion

A torsion spring is a type of helical spring that works by twisting its ends along its axis to exert a rotational or torque force. These springs are used in applications where rotational energy is required to maintain or return a component to its desired position.

©2024 All rights reserved. Site by AC