Start your custom quote:

custom catalyst-retaining springs by katy spring

catalyst-retaining springs

Applications of Catalyst-Retaining Springs

Reactors: In chemical reactors, catalyst-retaining springs keep the catalyst bed stable, ensuring uniform flow of reactants and consistent reaction rates.

Environmental Control Systems: Springs are used to secure catalysts that break down pollutants in air or water purification systems.

Manufacturing: Springs hold catalysts in place within manufacturing equipment, ensuring they are effective in processes like polymerization, cracking, or synthesis.

Benefit of Using Catalyst-Retaining Springs

Optimal Catalyst Positioning: Ensures that the catalyst is properly positioned for maximum contact with reactants, enhancing the efficiency of the chemical reactions.

Uniform Distribution: Prevents channeling or uneven flow, leading to more consistent and predictable outcomes.

Custom springs, From Concept to Completion

From the initial spring design to the manufacturing and delivery. Our best practices and quality assurance ensure you end up with the precise parts made just for your project. Every solution, designed for your needs.

- 1

- Spring Design

We’ll work closely with your team to design a custom spring solution. Already have a design? We’ll be able to jump through this step even faster.

- 2

- Custom Manufacturing

For over 25 years, we’ve produced a large array of custom springs in a variety of materials. It’s our speciality.

- 3

- QC & Delivery

Each and every step of our production process ensures trackable quality so your product is more than what you expect.

need custom springs manufactured?

What our customers say

“ Definitively I will Katy Spring in our preferred list of spring supplier, excellence and fast quoting service.”

-

Héctor G.

Precision Tools

“ Spot on. Let me get in touch with our customer to see how they want to proceed. Thank you for the quick...”

-

Joe H.

Oil Rig Design Engineer

“ I have at least three more good volume items to quote. I will get those over to you. Your pricing has been...”

-

Marsha R

Engineered Valves

quality is our guarantee

manufacturing quality since ‘99

At Katy Spring, we take the little things seriously. From the design and engineering quality to the way you feel through the entire process, we want to be your best manufacturer across the board. That’s how we do business.

Detailed Quoting & Estimates

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

Thorough Quality Control Checks

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

Trackable Schedules & Deliveries

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

24/7 Production Support

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

types and accessories of spring catalyst-retaining springs

- Catalyst Spring Gang Assembly - The catalyst spring “gang” assembly shown below provides more depth accuracy, time-saving insertion and removal, and greatly reduces inspection time.

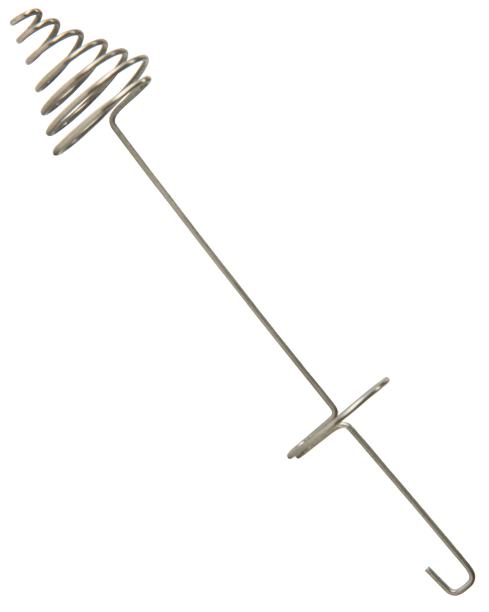

- Long-Stem Catalyst Spring - Long-stem catalyst springs are typically used in deep tube sheets. The crossbar at the bottom of the stem allows for faster inspection time.

- Catalyst-Retaining Spring - Catalyst-Retaining springs are springs that do not require any assembly. These springs are the most economically-produced springs but do not offer the multiple insertion and quick inspection benefits that the assemblies offer.

- Heavy-Duty Catalyst Spring - Heavy-duty catalyst springs are used to support heavier catalyst loading requirements.

- Large-Tube Catalyst Retaining Springs - Katy Spring offers catalyst-retaining springs for large tubes, up to 3” ID.

- Short-Stem Catalyst Spring - Short-stem catalyst springs are typically used in shallow tube sheets. The crossbar at the bottom of the stem allows for faster inspection time.In addition, the end configuration allows for hand insertion and retraction.

- Inlay Assemblies - Inlay assemblies are typically used in acrylic manufacturing applications. Thermocouple Catalyst Spring Gang Assembly

- Insertion and Retraction Tools - Katy Spring can assist with the design and manufacturing of custom insertion and retraction tools. These tools can be shipped with the springs to be inserted, saving time in searching for tools used for previous turnarounds.

- Twistie or Spirals - Twisties or spirals, typically used for deep tube sheets, can be supplied in various lengths and in various “spirals-per-foot” configurations. Catalyst spring can be added to the end.

- Fish-Tape Wire - Fish-tape wire provided in rolls like the one shown below, can be cut to almost any length and supplied and many different wire diameters.

- Punch Wires - Punch wires are can be made up to 45 feet long with custom-end configurations that can be adapted for different types of punch-wire equipment. Punch wires are typically shipped in custom-made pipes to ensure safe packaging.

other custom springs:

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC