Start your custom quote:

custom Double Bodied Tortion Springs by katy spring

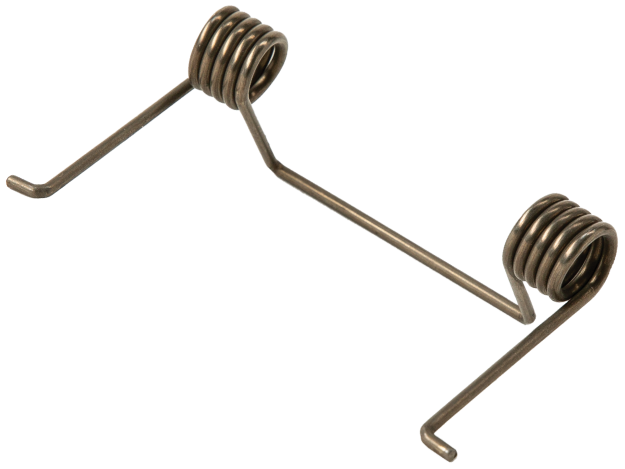

Double Bodied Torsion Springs

Components and Structure

Two Torsion Springs:

A torsion spring is a type of spring that works by twisting its ends along its axis. It stores mechanical energy when twisted.

Each torsion spring in a doubled body setup has its own coils and arms (the ends that extend out from the coils).

Connecting Section:

The two springs are connected, usually by a central wire or another mechanism that ensures they work in unison.

This connection allows the torque applied to one spring to be transferred and distributed to both springs.

Functionality

Torque Distribution:

When a force is applied to the arms of the torsion spring, it causes the springs to twist. In a doubled body torsion spring, this force is distributed between the two springs.

This distribution helps in managing higher loads and reduces the stress on individual springs, increasing the overall lifespan of the spring system.

Increased Range of Motion:

By having two springs, the system can accommodate a greater range of angular motion. This is beneficial in applications where large rotational movements are required.

The design can also help in achieving more precise control over the movement and force exertion.

Redundancy and Reliability:

The double body design provides a level of redundancy. If one spring fails or loses its effectiveness, the second spring can still function, providing a safety margin in critical applications.

Custom springs, From Concept to Completion

From the initial spring design to the manufacturing and delivery. Our best practices and quality assurance ensure you end up with the precise parts made just for your project. Every solution, designed for your needs.

- 1

- Spring Design

We’ll work closely with your team to design a custom spring solution. Already have a design? We’ll be able to jump through this step even faster.

- 2

- Custom Manufacturing

For over 25 years, we’ve produced a large array of custom springs in a variety of materials. It’s our speciality.

- 3

- QC & Delivery

Each and every step of our production process ensures trackable quality so your product is more than what you expect.

need custom springs manufactured?

What our customers say

“ Definitively I will Katy Spring in our preferred list of spring supplier, excellence and fast quoting service.”

-

Héctor G.

Precision Tools

“ Spot on. Let me get in touch with our customer to see how they want to proceed. Thank you for the quick...”

-

Joe H.

Oil Rig Design Engineer

“ I have at least three more good volume items to quote. I will get those over to you. Your pricing has been...”

-

Marsha R

Engineered Valves

quality is our guarantee

manufacturing quality since ‘99

At Katy Spring, we take the little things seriously. From the design and engineering quality to the way you feel through the entire process, we want to be your best manufacturer across the board. That’s how we do business.

Detailed Quoting & Estimates

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

Thorough Quality Control Checks

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

Trackable Schedules & Deliveries

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

24/7 Production Support

Once Katy Spring receives your files and specifications we will begin working on your custom quote.

ordering custom double bodied torsion springs

Double bodied torsion springs should be designed to coil out from the center rather than in from the ends so that they can be rotated in angular deflection. Double body torsion springs are found in automobile door systems and are commonly used as couplings between concentric shafts such as motor and pump assemblies.

Applications include:

- Major household appliances

- Medical devices

- Military devices

- Aerospace devices

- And more

- Specify a force with a tolerance (+/- 10 percent) at an exact compressed height rather than a definite deflection. Spring rate is the difference of two forces divided by the amount of deflection between those forces.

- Make Katy Spring aware of unusual conditions such as temperature, corrosive environments, impact force, and fatigue life.

- Specify the mandatory requirements only to Katy Spring, and leave the exact wire size and number of coils to the discretion of Katy Spring whenever possible.

other custom springs:

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC