Dec 4, 2011

Manufacturing Spring for the Medical Industry Part ll

Contact Us Phone: 281-391-1888 Fax: 281-391-0666

Please send inquiries to: sales@katyspring.com Ph. 281-391-1888

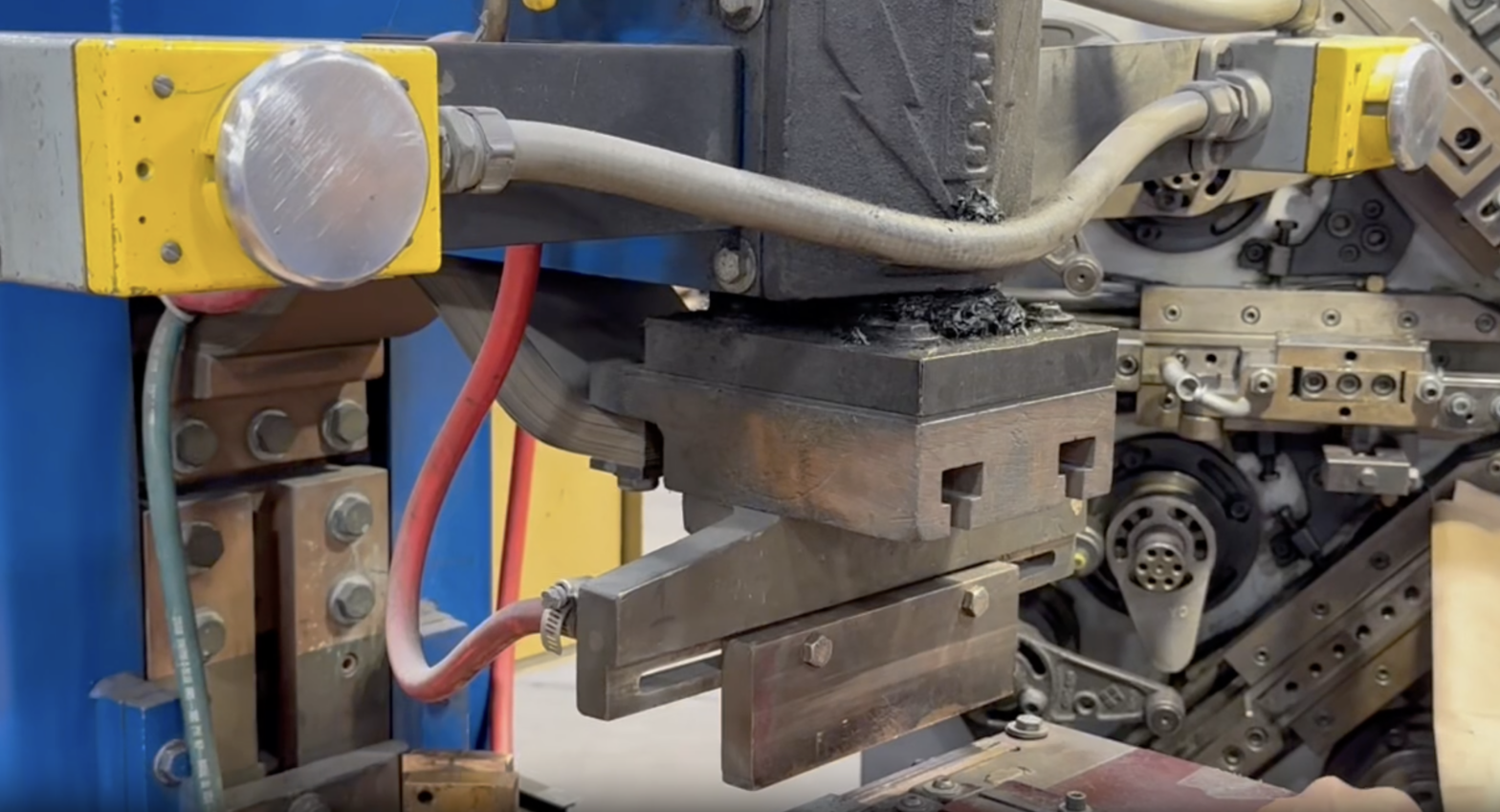

Manufacturing springs for the medical industry requires tight-tolerance spring manufacturing methods. Exotic spring-tempered materials such as Elgiloy, Inconel, Monel, and Hastelloy are used in the medical industry and are required in many medical spring applications. These types of materials can be found in all types of springs; compression springs, torsion springs, extension springs, flat springs, wire forms, as well as endless other types of spring-tempered forms. Still, many spring wire medical applications use three hundred series stainless steel spring wire. The stainless steel spring wire used in medical applications has special coatings, unlike the normal soap coating used to lubricate spring wire so that it runs through the spring coilers with less friction. The very small-diameter spring wire used in medical applications are diamond drawn which lubricates, but with no soap or lubricant chemicals. These types of medical products these springs are used in include and are not limited to; pacemakers, pill dispensers, medical pumps, hearing and sight aids, implants, prosthetics, implants, and guidewires. Guidewires are an interesting medical spring application. Guidewires are placed into arteries and veins to reach a specific organ such as the heart or liver. Guidewires are rigid which is why they are spring tempered, to allow doctors to maneuver them around vessels. The FDA is very involved with the approval of using guidewire devices. Strict guidelines are enforced with using guidewires not only by the FDA, but also by doctors themselves. It takes specialized spring manufacturing personnel and a spring manufacturing facility to manufacture the sterile medical spring products. The very small spring wire requires patience by the operators of the spring manufacturing equipment, as well as clean rooms needed for sterilized spring manufacturing. Medical springs require specialized packaging for most applications as well as specialized assembly such as laser welding. Medical spring manufacturing is not something that a spring manufacturer decides to do overnight. Much must be considered to enter into the medical spring manufacturing market.GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC