Custom Extension Springs Manufacturing

Extension Springs

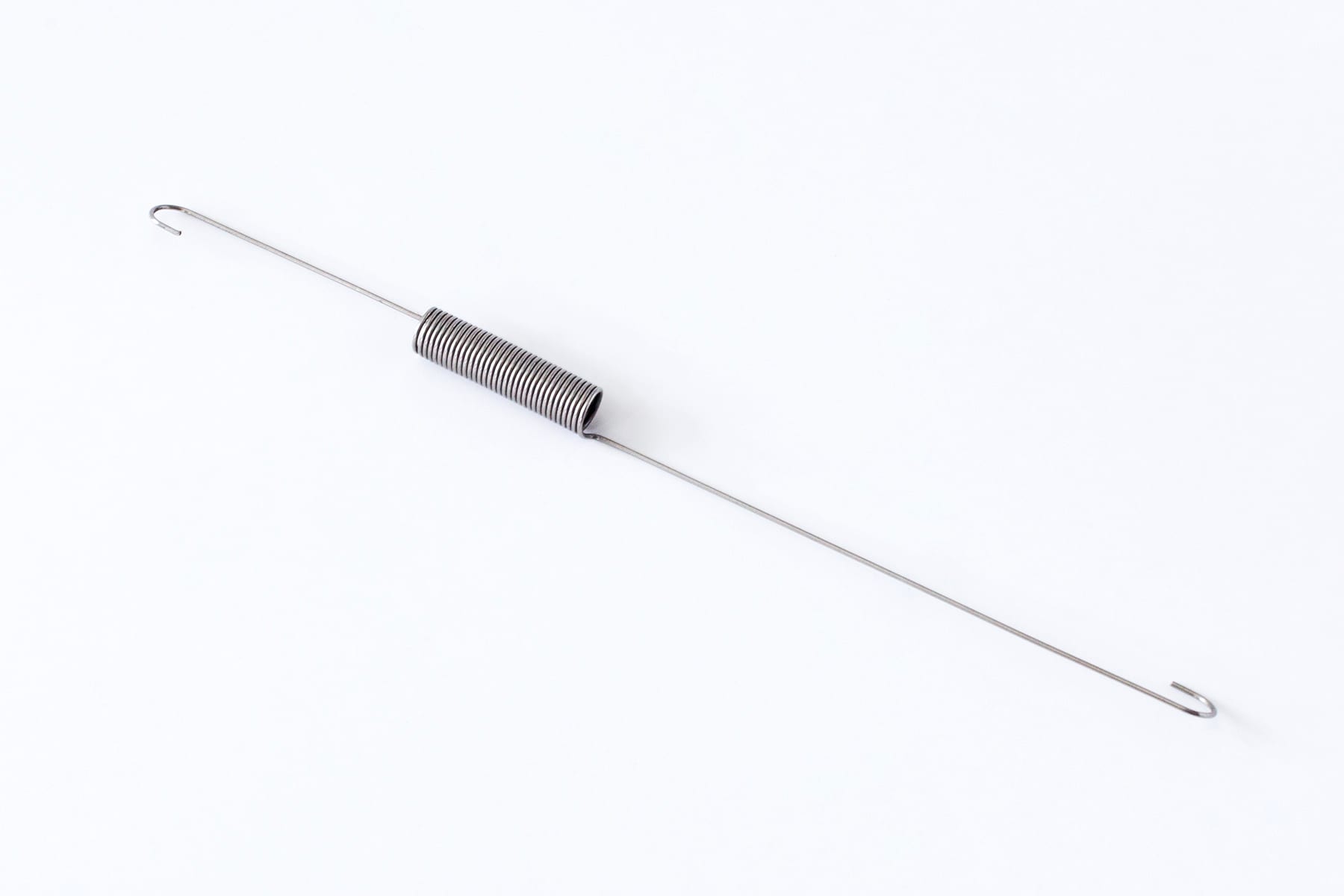

Extension springs are closed-coiled helical springs that extend under a pulling force. Many design considerations must be made with extension springs including initial tension, stress, deflection of hooks, and hook end types.

Below, several types of extension springs:

- Machine loop and hook over center

- Side Loop

- Full loop over center

- No hook

- Extended hook

- Hook end with swivel

- V-hook over center

- Double twisted full loop over center

- And many more

Extended Hook

Double Hook 180°

Double Hook with Loop on Side

Ordering Custom Extension Springs

Extension springs take longer to design because consideration must be given to stress due to initial tension, stress and deflection of hooks, special coiling methods, secondary operations, and allowance for over stretching in assembly.

There are many hook configurations to consider in designing extension springs. Several methods for designing extension springs can be used. The easiest way to order is to contact Katy Spring with parameters including force needed, space limitations, free length, outside diameter, initial tension, and working environment. Force calculations can easily be made using spring design software.

Katy Spring can assist in making the right choice.

(281) 391-1888 | Fax (281) 391-0666

Helpful List

Below is a list of notes to keep in mind when ordering custom extension springs from Katy Spring:

- Extension springs should be stressed about 10-15 percent lower than compression springs to allow for overstretching at assembly and to reduce hook stresses.

- At least 10 percent of the maximum force should be in an extension spring’s initial tension.

- Full hooks deflect under a load equivalent to about half a coil, therefore deduct one coil from the calculated number of coils determined by design to allow for deflection of two hooks. For example, if not allowed for, a ten coil spring would be ten percent low of load. Each half hook deflects approximately equal to one tenth of a coil.

- All coils are active in an extension spring, allowance should be made for hook deflection.

- For regular hooks, the distance from the inside the hook to the body of the extension spring is about 75 percent of the inside diameter.

- Specifying the relative position of the hooks adds cost to extension springs. Do not specify position unless it is important. Also, avoid using large, extended or special hooks where possible, as they add cost to extension springs.

- Keep the outside diameter of a hook the same as the extension spring OD so the hook can be made by bending up a regular coil. Keep the tolerances high in regards to hook opening. Swivel hooks and coned ends reduce breakage, but are often quite expensive. An extension spring with a reduced OD may often suffice to reduce breakage.

- Electroplating does not deposit a thorough coating between the coils of extension springs, such springs should be extended during plating.

- Specify forces at extended lengths between hooks, not at amounts of deflection.

- If high stresses cannot be achieved consider using compression springs fitted with drawbars.

- Specifying two forces is often expensive, consider using a rate when appropriate.

Contact Us

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you with spring purchases.

Learn more about Compression Springs Terms.