Oct 25, 2011

Katy Spring Flat Spring Design | Press Release 10-25-11

© Copyright 2011 KATY SPRING & MFG, Inc.

Phone: 281-391-1888

Fax: 281-391-0666

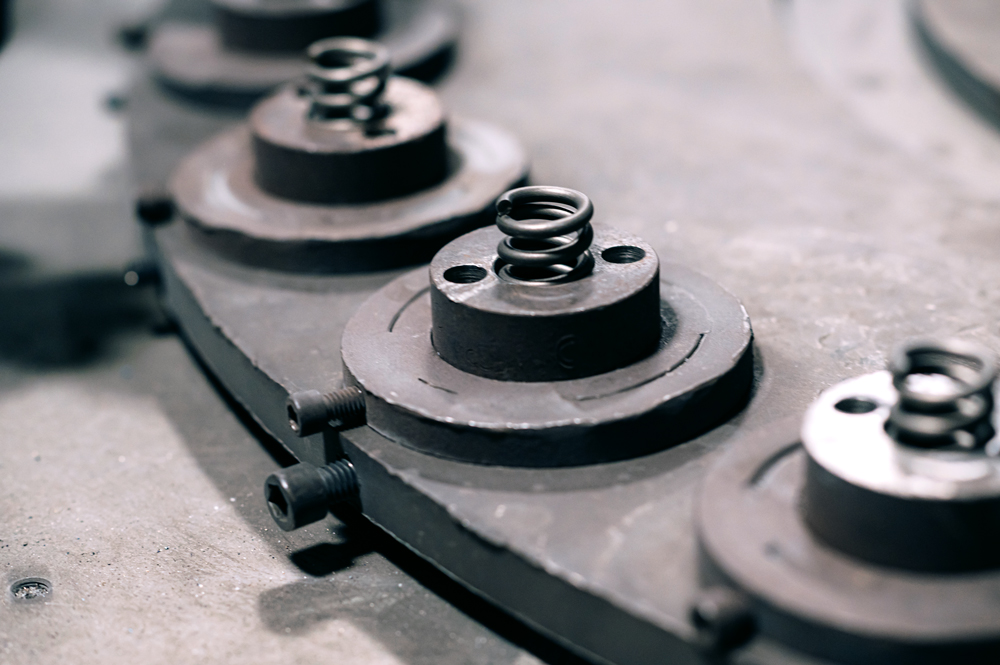

Flat Springs come in endless varieties of shapes, materials and functions. Flat spring manufacturers form flat springs from flat, strip, spring material that are produced with either squared or rounded edges. They are considered flat springs, because they are made from flat stock spring steel and perform like coil springs, storing and releasing energy.

Flat springs are typically custom springs and are made from jigs and specialized spring manufacturing tooling built by the spring manufacturer as a one-time spring manufacturing.

Flat spring design formulas can be less accurate than compression spring, extension spring and torsion spring formulas with increased deflection. It€™s recommended that assistance is obtained from the spring manufacturer in designing flat springs. The spring manufacturer will need to know the space, approximate spring load, and environment that the flat spring will work in, in order to assist with the flat spring design.

Additional information the spring manufacturer may need to know about your flat spring design, is the direction the flat spring will bend. Additional spring stresses will occur if the flat spring deflects against the grain, or where there are sharp radiuses or where holes are made in the flat spring material.

Because a flat spring may perform any number of functions, there are infinite possibilities for flat spring design. This is why flat springs normally require special tooling. Flat spring tooling can be complex or simple. Depending on the design of the flat spring, the flat spring tolerances specified, and the quantity required. Because of these variables, check with the spring manufacturer to make sure the flat spring design is cost efficient and sensible to manufacture.

When flat spring material is blanked or stamped a burr may occur which can be removed by tumbling. This may not be a good operation for all flat springs such as small, thin flat spring parts. Sometimes it is possible to control the flat spring burr so it will not interfere with the flat spring application.

It is a good practice on flat spring design to provide liberal radii on corners and formed bends. It is also good to provide sufficient length in these bends to eliminate unnecessary secondary operations. Also, keep all holes well away from edges and bends.

Flat springs begin as an annealed spring strip material and are hardened after forming. Flat springs can also be made from hardened spring strip which is then stress relieved. Because most flat spring is hardened after forming, Flat spring design typically uses commercial stamping tolerances as a guide. Special flat spring manufacturing processes, like spring manufacturing jigs and fixtures, can aid in holding very tight tolerances

Shipping and Billing Address:

3535 Schlipf Rd

Katy, TX. 77493

Phone: 281-391-1888

Fax: 281-391-0666

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC