Feb 11, 2019

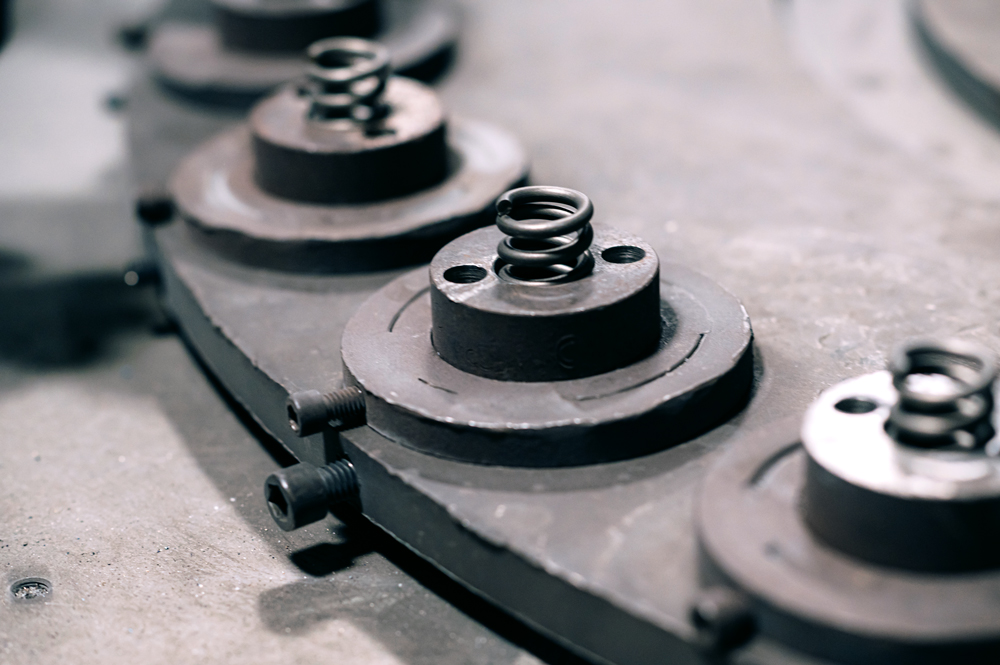

Picking a spring with the proper action, material, and feel can be critical to the success of a medical device.

Choosing or designing the right spring is especially critical when it comes to medical devices.

Springs can be used on various medical devices including; x-ray machines, bed lifts, and drug cabinet dispensers and surgical devices.

Here are some things to keep in mind when choosing the right design or spring.

Choose the right configuration;

- Compression Springs - for compression force

- Extension Springs - for pulling forces

- Torsion Springs - for torque forces

- Flat Springs - for applications where the above will not work in the application

- Wire can run as low as .003", most spring coilers can manufacture starting at .007"

- Material types for medical springs are many times stainless steel. Carbon steel generally has better spring properties, but is typically used is an environment that is non-corrosive or a non-sterile environment.

Other consideration;

Sometimes when testing a device, especially a medical tool using a spring, feel is important. The spring manufacturer can assist with designing the feel desired in a medical device using a spring.

Additionally, spring manufacturers can assist with design and all the components of spring design including; spring ends, size envelope, weight of the spring, movement, trap and tolerances, cost-saving input, and much more.

There’s typically more than one solution to solving a spring problem. Leave it to the spring experts to help guide medical designers in finding their unique solution.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC