Jan 12, 2023

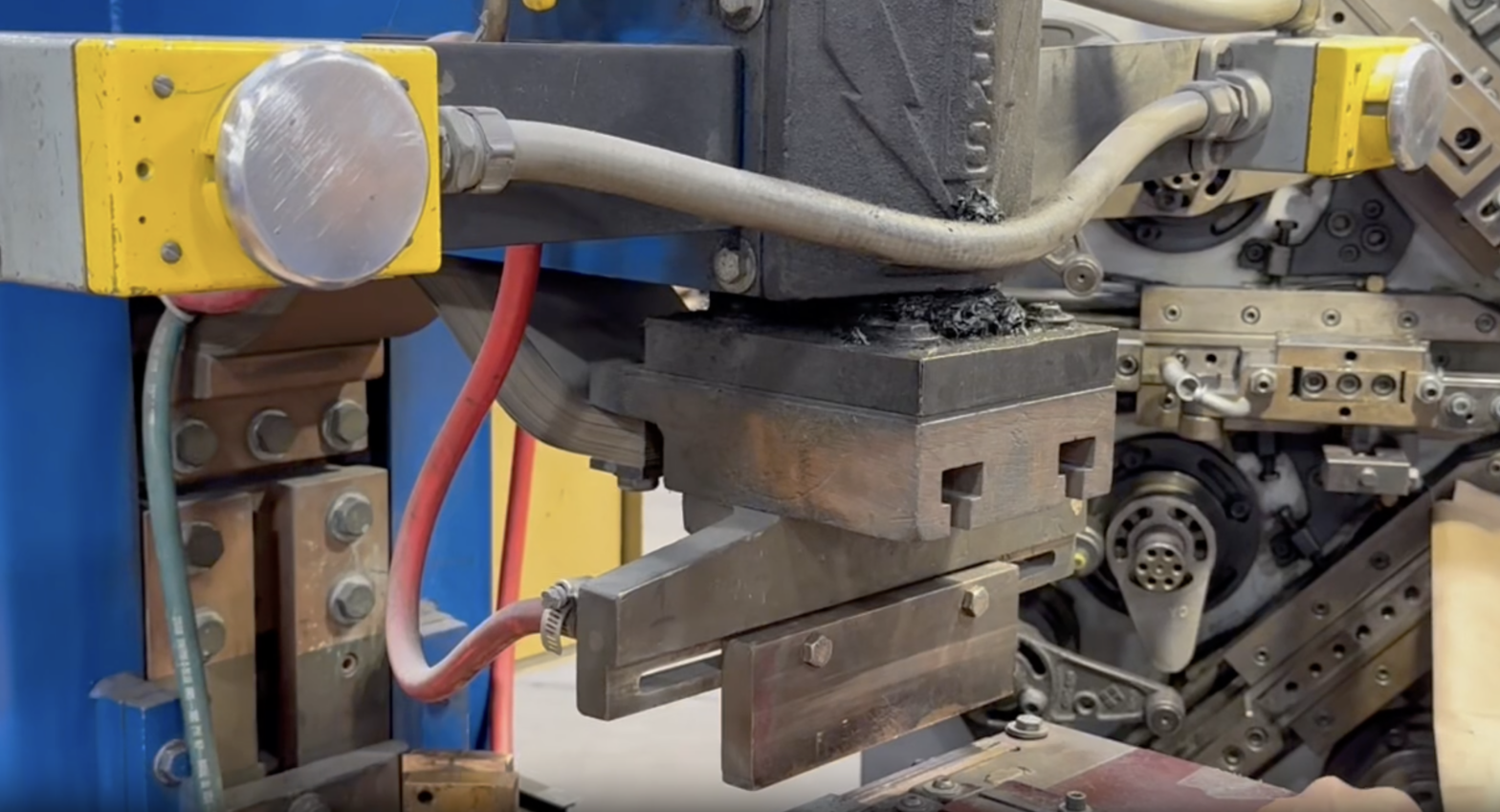

That is one long spring…164” to be exact! This spring, made from .250” music wire, is shown here being stress relieved through an inline oven.

The oven temperature is about 600 degrees F. The heat causes the spring to relax or “normalize” to hold its configuration. By nature, spring material has memory and wants to return to its original formation; the applied heat prevents that from happening.

This particular spring can be cut into various lengths and formed with different end configurations. They are ultimately used as torsion springs and are used in roll-up applications such as security door assemblies, industrial door assemblies, and tarp assemblies for the trucking industry.

That is one long spring…164” to be exact! This spring, made from .250” music wire, is shown here being stress relieved through an inline oven.

The oven temperature is about 600 degrees F. The heat causes the spring to relax or “normalize” to hold its configuration. By nature, spring material has memory and wants to return to its original formation; the applied heat prevents that from happening.

This particular spring can be cut into various lengths and formed with different end configurations. They are ultimately used as torsion springs and are used in roll-up applications such as security door assemblies, industrial door assemblies, and tarp assemblies for the trucking industry.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC