Feb 15, 2012

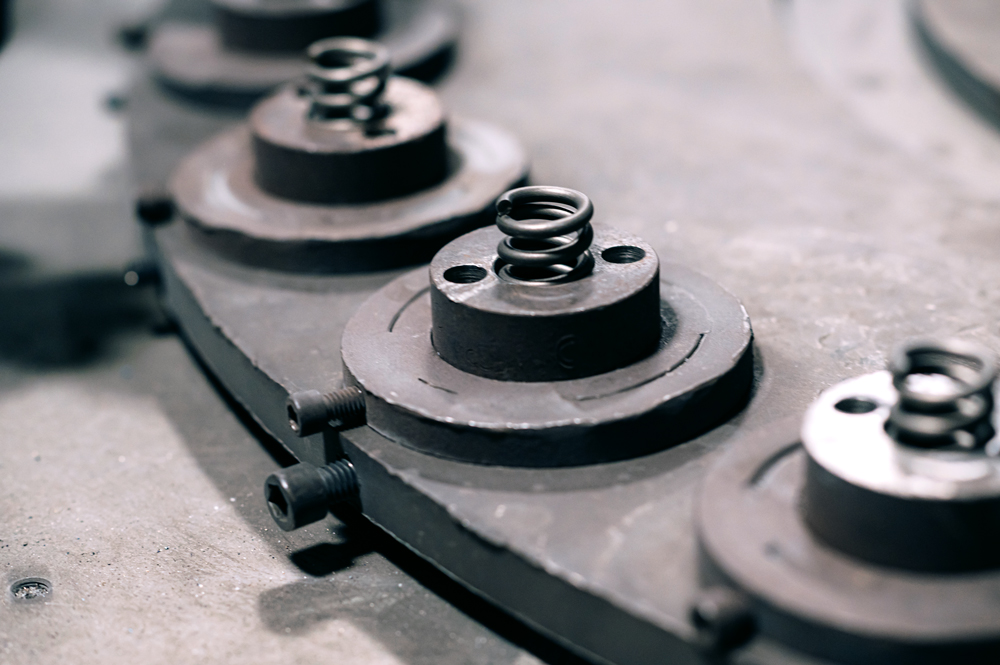

Extension Spring Geometry

Extension springs are typically manufactured with initial tension. Extension spring initial tension is the force required to break apart the adjacent coils. This fabrication method allows consistent free length.

Since the extension spring initial tension is not zero, the spring rate is not truly linear when measured from the unloaded position. However, once the initial tension is overcome, the extension spring does behave linearly.

Extension Spring Shear Stress

After the initial tension is overcome, the extension spring can be analyzed as a compression spring with a negative force. The maximum shear stress in the extension spring increases with the load.

Extension Spring End Stress

When considering a regular extension spring hook, the geometry of the hook often causes stress concentration which leads to failure.

Extension Spring Safety

With an extension spring, there is no such safety geometry, as with a compression spring, since the extension spring is in tension. For this and other reasons, extension spring maximum working stresses are typically limited to three-fourths of those for compression springs of similar geometry and spring material.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC