May 3, 2012

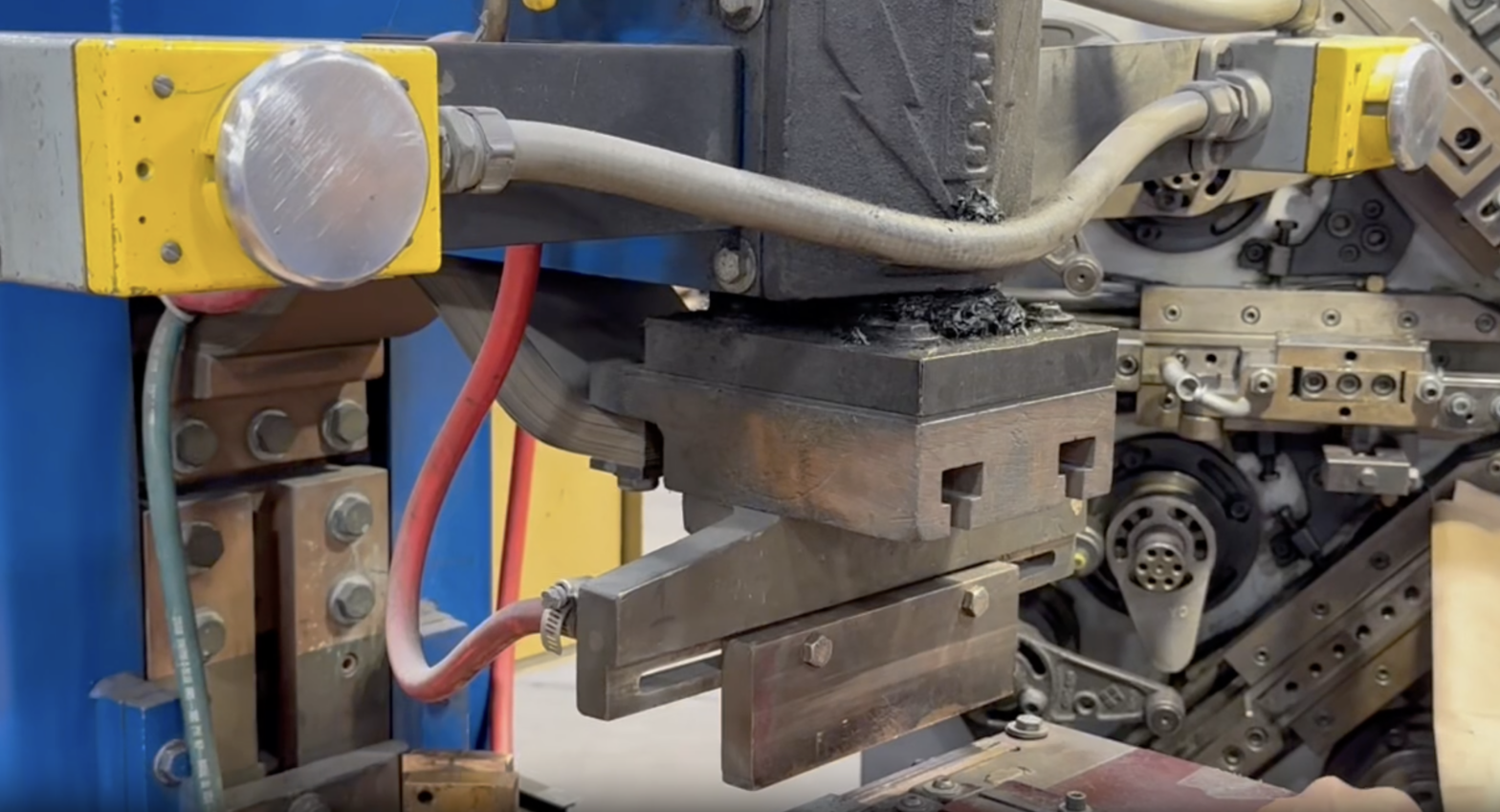

For springs manufactured up to 0.75 in diameter in a cold-wound environment, two techniques can be used. One consists of winding the wire around a shaft or arbor. This can be done on a spring-manufacturing machine, a spring lathe, even an electric hand drill with the mandrel secured in the chuck, or a hand-winding spring manufacturing machine with a hand crank. A guiding mechanism, for example, a lead screw on a lathe is used to align the wire into the desired pitch as it wraps around the arbor The wire may also be coiled without a mandrel. This is generally done with a central navigation computer (CNC) spring manufacturing machine. Springs made on Automatic Spring Manufacturing Machines Spring-tempered wire is pushed forward over a support block toward a grooved head that deflects the wire, forcing it to bend. The head and support block can be moved relative to each other in as many as five directions to control the diameter and pitch of the spring that is being formed. For extension or torsion springs, the ends are bent into the desired loops, hooks, or straight sections after the coiling operation is completed. Hot winding is a spring manufacturing technique used for thicker wire or bar stock. The spring material can be coiled into springs if the metal is heated to make it flexible. Standard industrial coiling machines can handle steel bars up to 3 inches in diameter, and custom springs have reportedly been made from bars as much as 6 inches thick. The steel is coiled around a mandrel while molten hot. Then it is immediately removed from the coiling machine and plunged into oil to cool it quickly and harden. At this stage, the spring steel is too brittle to function as a spring, and it must subsequently be tempered. Scott Pitney Katy Spring & Mfg., Inc. Add us to Facebook: http://facebook.com/springmanufacturer

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC