May 18, 2012

Katy Spring Announcement 5-18-12 The Future of Spring Manufacturing Demands of the rapidly growing high-tech industry, including computers and cell phones are pushing spring manufacturers to develop reliable, cost-effective techniques for making very small compression and extension springs. Springs that support keys, for example, on touchpads and keyboards are important, but there are less apparent applications as well. For instance, a manufacturer of test equipment used in semiconductor production has developed micro-compression spring contact technology. Thousands of tiny compression and extension springs are bonded to individual contact points of a semiconductor wafer. When this wafer is pressed against a test instrument, the compression springs compress, establishing highly reliable electrical connections. Medical devices also use very small compression and extension springs. Coiled springs that have been developed for use in the insertion end of a catheter or an endoscope are one example. This product uses spring-tempered stainless wire about the same size as human hair. Spring manufacturers that developed these springs are attempting to make them even smaller. The ultimate miniaturization of compression springs thus far was accomplished in 1997 by an Austrian chemist. The chemist built a molecular spring by stringing 12 carbon atoms together and attaching a vitamin B12 molecule to each end of the chain by means of a cobalt atom. In the relaxed state, the chain has a zigzag shape; when it is wetted with water, however, it kinks tightly together. Adding cyclodextrin causes the chain to return to its relaxed state. No practical application of this spring has yet been found, but research continues.

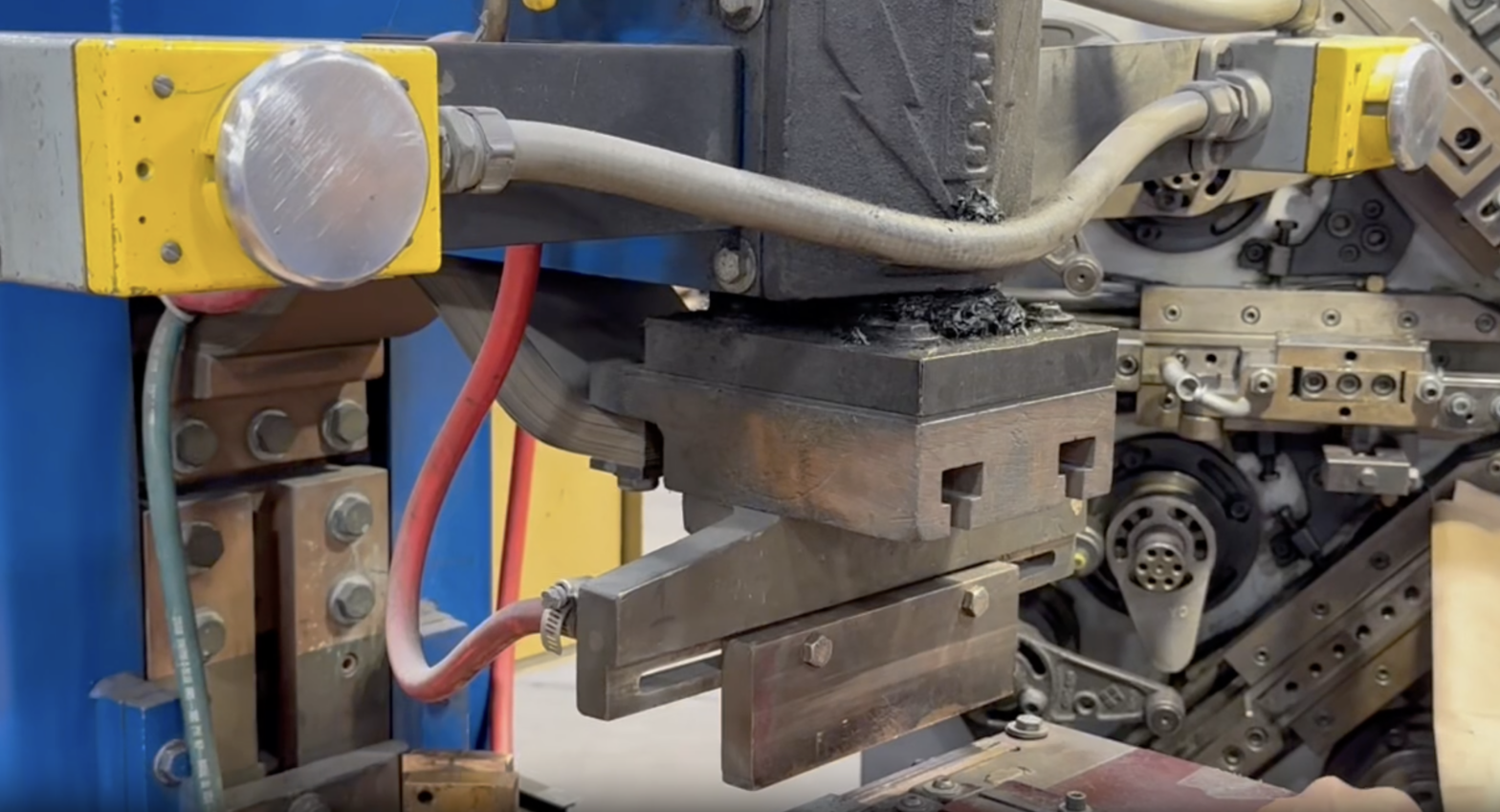

Phone: 281-391-1888 Fax: 281-391-0666 Please send inquiries to: sales@katyspring.com Attn: Mark West Ph. 281-391-1888 Steel Springs & Wire Forms Spring Manufacturer

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC