Jan 16, 2018

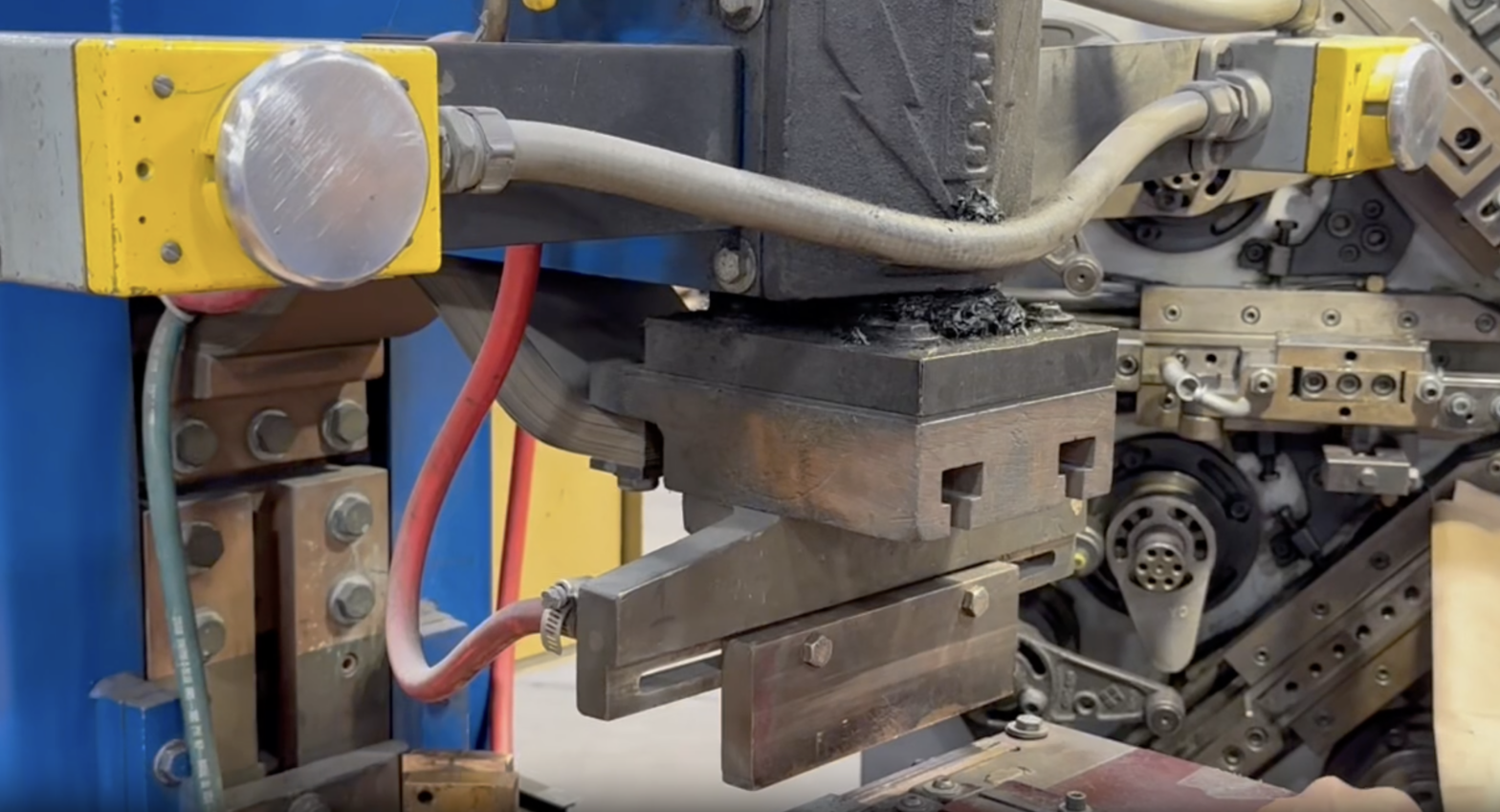

It’s really amazing to look back eighteen-and-a-half years from where we started with just one W-11 Torrington spring coiler to now owning over forty-two, what we call Work Centers. Work Centers are basically pieces of equipment where we make springs, wire forms, and flat formed metal components. The support equipment list for these Work Centers are too many to mention, the point being, we’ve come a long way from only making springs in a wire size range from .020 to .072and with no grinding requirements. This very narrow capability in the early days put us in a position of subcontracting the majority of our orders, which was roughly ninety percent of all processing. Once we purchased a grinder (the first check bounced by the way) this allowed us to bring much of the work we currently had back in-house; however, we continued to subcontract well over half of our jobs for the first few years. As time went on, the business grew along with the customer base and so did our capabilities. Katy Spring has never bet on the come in terms of buying equipment. Every capital investment has been the result of an immediate need for the equipment and that holds true today. The decisions are also made based on current and historical workload, the support equipment and training demands required when purchasing a machine. We have a good idea of the equipment capabilities prior to purchasing, however, we work closely with the equipment vendors to ensure we completely understand the capabilities, maintenance requirements, and training needed to make the equipment productive from the start. We even go as far as sending drawings to the vendor to inquire about run speeds and set up times so that we are making good, informed decisions about the investment we are making. So far this strategy has worked, as we have never made a purchase for new equipment that has turned out to be a flop. Katy Spring will continue to invest in the latest spring and wire form technology as it continues to develop and change every year. The CASMI show, held every two years in Chicago is a great showcase for spring equipment vendors to demonstrate the latest in spring technology. Katy Spring sends a team to every show to make sure that our employees stay informed and are on the front lines of the decision-making process, bringing the best the industry has to offer, to our valued customers.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC