Jan 3, 2019

What are torsion springs?

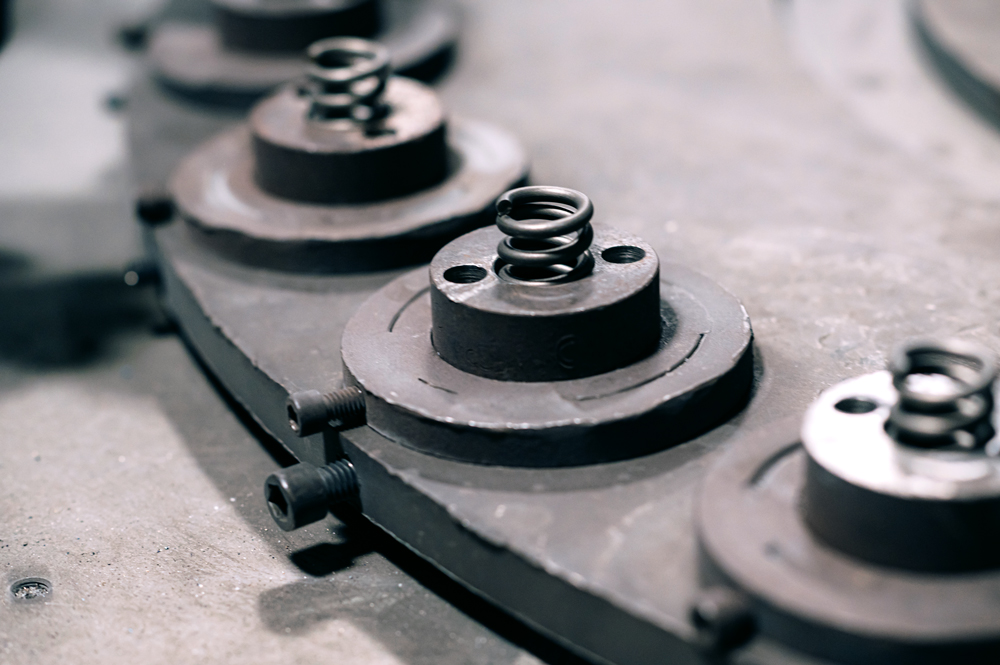

Spring manufacturers will often work closely with the valve industry, because coil springs are an important component of valve parts. There are many different aspects of valves, and the particular design of any given valve will depend on its function and target application. However, the main components include:

- Body: The body and bonnet are the main part of the valve, forming the vessel (or casing) that contains the fluid that goes through the valve. A valve body is usually constructed out of a metallic material such as brass, bronze, iron or alloy steels. Sometimes plastic bodies are suitable for valves that are intended for use in low temperature and low pressure environments. In these cases, PVC, PVDF and glass-reinforced nylon are typical materials for the valve bodies

- Port: The passages, or ports, that allow flow into and out of the valve are an integral aspect of the valve body. Ports are opened up or obstructed by the disc, which controls the fluid flow. The most common types of valves have two or three ports, but there are multiple port valves that are used in special applications. No matter how many ports are on the valve, all of these pieces of equipment have some means of connection at the ports. These connections might be male or female threads, socket-type connection or butt-type connections.

- Disc/Rotor/Valve Member: Another important component of valve parts is the disc, or valve member, which is located inside of the valve body and partially or fully blocks the valve’s flow. The valve body stays stationary within the fluid, but the disc within the valve is moveable so that it can control the fluid’s flow. Valve Discs come in a variety of shapes; however, the disc shape is traditional.

- Seat: The valve seat is the inside surface of the body that contacts the disc to form a leak-tight seal when the valve is shut. The body and the seat come in either one piece of solid material, or seat might be an individual piece that is attached to the inside of the valve body.

- Stem: A stem is a rod that spans the inside and outside of the valve and transmits the motion that controls the internal disc from the outside. This stem is joined to the disc/rotor, as well as to the handle, and also goes through a bonnet if there is one on the valve.

- Bonnet: Bonnets act as a cover for the entire valve body. This component is usually semi-permanently fixed onto the valve body. Manufacturers place all internal parts of the valve into the body, and then they attach the bonnet to hold everything inside. A user must remove the bonnet in order to perform maintenance on the valve.

- Spring: Valves often have a coil spring that is used for spring-loading. The spring shifts the disc into position, but by default allows enough control to reposition the disc. A relief valve will commonly use a spring to keep the valve shut; but excessive pressure can force the valve to open up against spring-loading. These springs may

- Valve Ball: Only heavy duty, high-tolerance applicants need valve balls, which are made of stainless steel, brass, nickel or a similar material. Sometimes these balls are made of plastic, such as PVC or PVDF.

Katy Spring is a full service, custom metal forming company that offers clients around the world the absolute best in coil springs and other metal components. Unlike some springs manufacturers, Katy Spring is ISO Certified, which means you can rest assured that your metal products are engineering using the highest quality standards and environmentally responsible. Whether you need springs to complete your valve parts or are looking for other types of spring products, contact the professionals at Katy Spring at 281-391-1888.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC