Jan 3, 2019

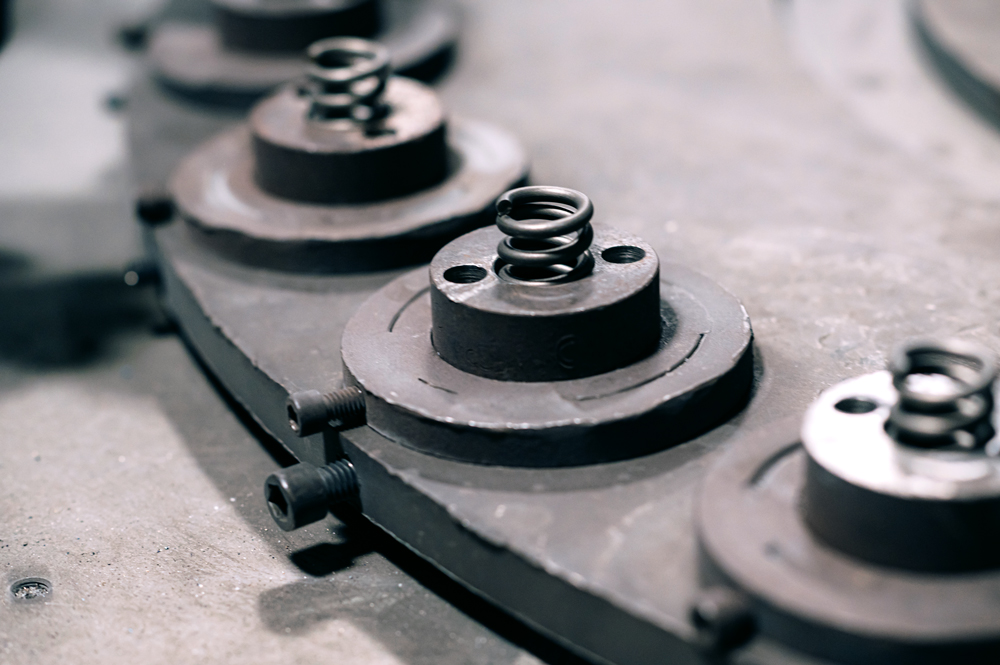

Every company that uses commercial springs needs to consider obtaining spring load testing equipment. Quality Houston spring manufacturers can help you decide which product can help you foresee load testing problems, avoiding a spring load that is not inadequate. It is vital to have a full range of springs, so that you are not caught in the dilemma of using a compression spring that is really too large for the application. Depending on the equipment’s accuracy, you should not use a load that is below 10% to 20% of the scale’s capacity.

Consider the following when choosing load testing equipment:

Load height and cell calibration: In order to stay accurate, spring load testing equipment has to be calibrated regularly. The master weights need to be traceable to the NIST, and load cells should be calibrated and tested through the range of the tester to ensure that the load cell is linear. Also, the height readings need calibration, using gage blocks, throughout the scale’s range.

Load cell deflection: Since every load cell deflects the applied load, it is important to compensate for this load deflection when testing compression springs. Of course, electronic spring load testers do this automatically.

Load cell alignment: The top platen should be parallel to the load cell platen, which can be done by brining the platen down onto a gage block and moving it around to the outside of the cell. The block and the load cell should be parallel to each other, within a fraction of an inch. This type of precision can be accomplished using shims or adjusting screws.

Leaning effect on the load: Springs tend to lean a little bit, which is sometimes referred to as “squareness”; and this leaning can sometimes effect the load testing equipment. When there is significant variation between checking the spring standing on one end and checking it on the other, the customer an supplier need to agree on a single measurement method.

Hysteresis and friction: Because springs touch the fixturing, friction is always a concern. Also, because the coils wind up when compressed and the end coils twist and move on the platen, there is hysteresis, even when the user is testing a compression spring is not over a pin. Oil can reduce that friction, but the best solution is to test the load while it is approaching the load point, and then to test it again after going past that point. This method averages out the friction or hysteresis.

For all of your compression spring and spring load testing equipment, turn to the Houston spring manufacturers at Katy Spring. We have the expertise and equipment it takes to keep your company complete applications and product orders efficiently and safely. Call us today at 281-391-1888.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC