Jan 3, 2019

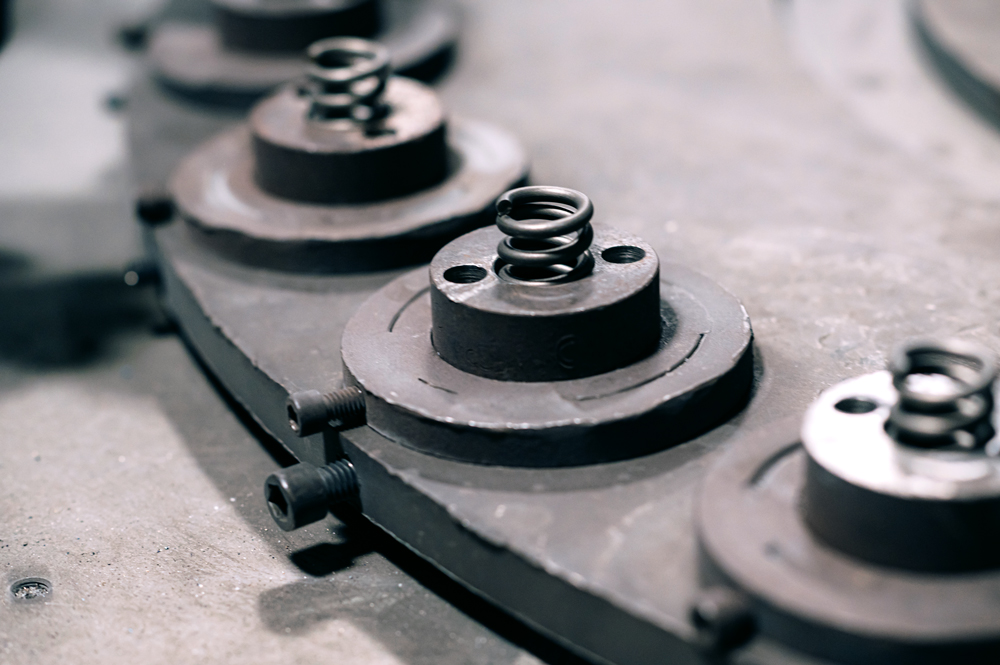

Spring Cycle Life

The cycle life of a steel spring cannot be determined (only predicted) as many variables determine a spring’s cycle life; i.e. the raw material, the environment, how the spring is used, etc. However, testing springs is a specialty of Katy Spring and we will uncover the cycle life of your springs through various cycle tests.

What is Spring Cycle Testing?

Spring cycle testing is conducted to test a spring’s (or several springs simultaneously) fatigue life in the spring’s application or its duplicate application. The spring deflects between its working load points repetitively as the loads are checked periodically for fatigue or loss in force. Katy Spring can cycle test all types of springs including Compression Springs, Extension Springs, Torsion Springs, Flat Springs along with and including the many types of materials springs are made with; Stainless, Carbon Steel, High-Nickel Alloys, Brass and Phosphorous wire.

What is Spring Fatigue?

Spring fatigue is an issue where springs subjected to cycle loading, the force of the spring varies between two load point values over a period of time. For example, the valve springs in a car's engine can be subject to fatigue and over time, excessive cyclic stresses from fatigue can cause the spring to fatigue or even fail.

What are some ways to avoid Spring Fatigue?

The short answer is: a good spring design. Far too often, the spring testers at Katy Spring are helping customers that have created a device that needs a spring. However, there may not be enough space in the device to design a spring that will have adequate load values to support the devices stored energy demands, thereby causing fatigue or failure in the spring and eventually in the device.

Sometimes when it’s only possible to work within a limited space, a spring’s fatigue life can be improved with shot peening, raw material upgrades, or pre-setting.

Other factors that can help a fatigue problem are due to the application, and can be improved. Corrosion, buckling, coil clash, and ID/OD interference are all possible problem areas that can often be improved. Let the springs manufacturer, Katy Spring & Mfg., assist you in improving your spring’s design.

What else should I know about Spring Fatigue?

A spring fatigue problem starts with the development of a microscopic crack which grows with every cycle. When the stress in the crack reaches the maximum tensile of the spring's material, the spring will break where the micro crack started. It should be noted that material with the same chemical analysis and strength can have different fatigue results.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC