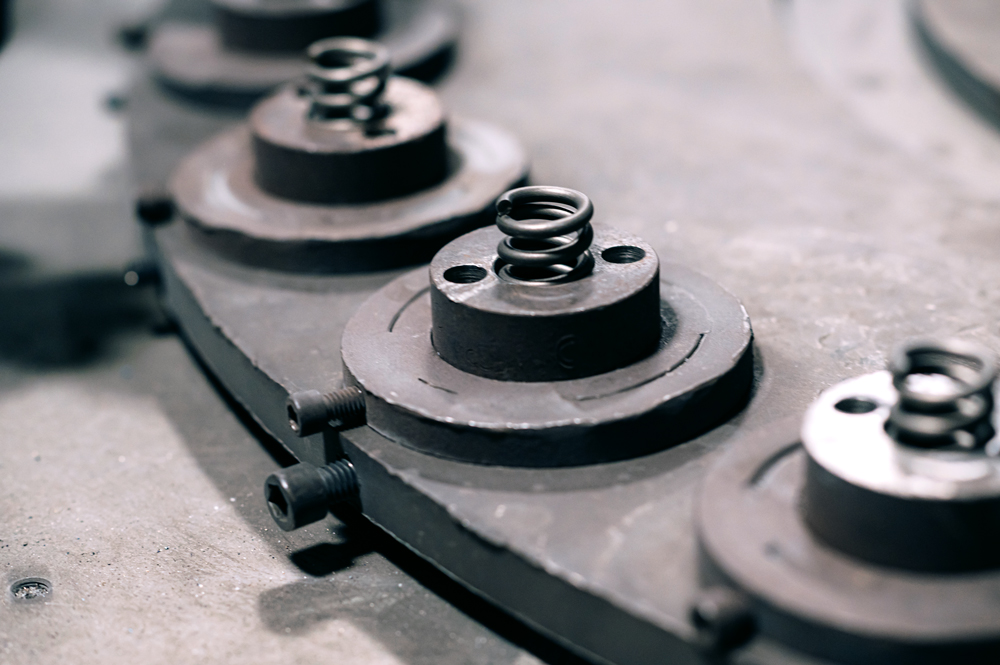

We are happy to provide compression spring information to our customers and potential customers. Katy Spring is a premier manufacturer of an assortment of springs.

Compression Spring Information — Types

Compression springs are used individually or in conjunction with each other. They should be stress relieved to remove residual that forms stresses during the coiling operation. Depending on design and space limitations, compression springs may be categorized according to stress level. For instance, round wire is predominant because it is readily available and adaptable to standard coiler tooling.

Some compression springs can be compressed solid without permanent set. An extra operation for removing set is not needed because these springs are designed with torsional stress levels when compressed solid. They do not exceed about 40 percent of the minimum tensile strength of the material.

Another type of compression spring can be compressed solid without further permanent set after set has initially been removed. These may be pre-set by the spring manufacturer as an added operation. These are springs designed with torsional stress levels when compressed solid that usually do not exceed 60 percent of the minimum tensile strength of the material.

Lastly, there are compression springs that cannot be compressed solid without some further permanent set taking place because set cannot be completely removed in advance. These springs involve torsional stress levels which exceed 60 percent of the minimum tensile strength of the material.

Popular Materials Used in Compression Springs

Music wire, hard-drawn MB, oil-tempered MB, and stainless steels are the most popular materials used in the manufacture of compression springs. Alloy steels such as chromium-silicon and chromium-vanadium are often used. Copper-based alloys such as beryllium-copper, phosphor-bronze, and spring brass are occasionally required, as are the proprietary nickel-based alloys such as Inconel, Monel, Ni-Span C, Elgiloy and so on.

Determining wire size is part of the design method process for compression springs. The methods used for design evolved from trail-and-error method observations all the way up to today's modern methods of spring design software which is incorporated by Katy Spring to assist our customers with wire size selection.

The least expensive and most used type of end, where the index D/d is above 10, is with closed ends, not ground; this type is especially satisfactory for light wire sizes less than .031 in. in diameter. The second most useful type, especially where small load tolerances or minimum buckling is required, is the "squared and ground"; this type also provides more uniform loading and will stand upright without tipping. The open ends and the open ends ground are seldom used, as they often tangle together during shipping; they cannot stand upright and do not exert uniform loads.

More Compression Spring Information

The outside diameter of a compression springs increases when deflection occurs. This change is because the slope or angle of the coils relative to the axis of the spring changes when deflection takes place. Allowance for this change should be made when a compression spring is housed in a tube to prevent friction or binding which can cause increased stresses and subsequent early failure.

Compression springs subjected to the dynamic effects of vibration, natural frequency, and surge and rapid force oscillations may have stresses increased as much as 40 percent or more. This is due to the inertia effect of the coils because suddenly applied forces make the first, second and third coils deflect more than other coils, and this explains why many springs break on one of these three coils. Most fractures occur on the third coil due to coil clashing.

Reduction of surge and resonance with harmonics in compression springs is usually accomplished by coiling one or two active coils near one end at a reduced pitch. These coils then close up and come together, thereby changing the natural frequency of the spring. Other methods to reduce surging include using two springs, one within the other, stiffening the spring to increase the force, or by using square or rectangular wire.

Buckling of helical compression springs often occurs when the free length is four times more times the mean diameter. The amount of deflection and the slenderness ratio are the dominating factors. The type ends is important, and for most applications where buckling occurs, it is highly desirable to have the ends closed and ground. Such springs should be guided over a rod or in a tube to retard buckling, and the rods or tubes should be lubricated to reduce friction.

Please visit our other pages for more compression spring information and compression spring terms.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC