May 21, 2019

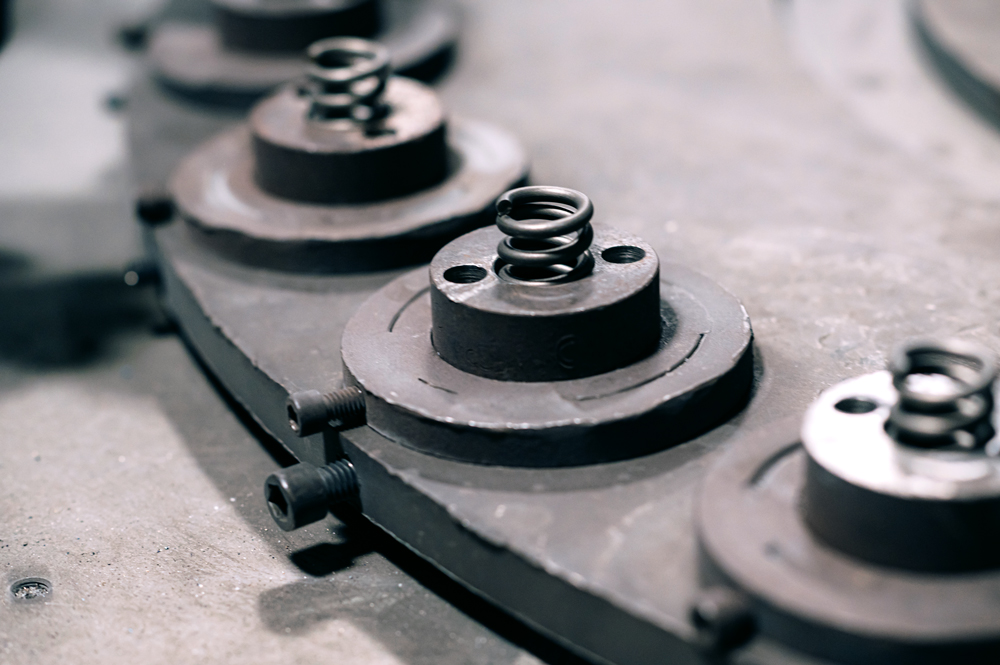

We hope you enjoy this blog post about torsion springs. It is a follow up to our main page, which you can visit here. There are several methods for designing torsion springs, and the easiest would be to contact Katy Spring with parameters including:

• Force needed

• Space limitations

• Shaft size

• Maximum body length allowed

• Environment the spring is used in

• Number of deflections

Design

Calculations can be done manually but are done much easier with spring design software. Torsion springs should always wind up from the free position—never to unwind from the free position. As they wind up, torsion springs reduce in diameter and their length becomes longer. Such springs should be supported over a rod whenever possible. Some spacing should remain between coils to minimize friction which can alter torque and deflection.

Torque

To define, torque is a force that produces rotation. Torsion springs exert force in a circular arc in which the arms rotate about a central axis. The stress is in bending. In the spring industry it is customary to specify torque with deflection or with the arms at a definite position. Formulas for torque are in inch pounds. When a force is specified at a distance from the centerline, the torque, is called the moment, is equal to the force multiplied by the distance.

Catalog and Stocking Program

Before spending hours searching through a spring catalog, let us know what you’re looking for and we can search for you. We have thousands of part numbers in our stock spring catalog. Provide us with as much information about the spring application as you can, and we’ll do the leg work for you.

As for our stocking programs, whether it’s a blanket order, a Kanban System, or a JIT System, our long-term stocking agreements are one of the best ways to improve standardized pricing, reduce inventory, and improve lead times. With finished goods on our shelves and not yours, it is a true win/win.

Experience You Can Trust

Katy Spring has been ISO Certified since 2004. We have many talented personnel that can assist engineers with spring design, saving them time and money with our spring design software. The spring design software helps us to avoid tolerance traps, advises us of potential yielding problems, helps with fit and function, material selection, and much more.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC