Jul 29, 2019

Katy Spring is a custom manufacturer of springs made from carbon steel, stainless steel, music wire and titanium, and specifically, chemical industry springs made from .125 stainless steel.

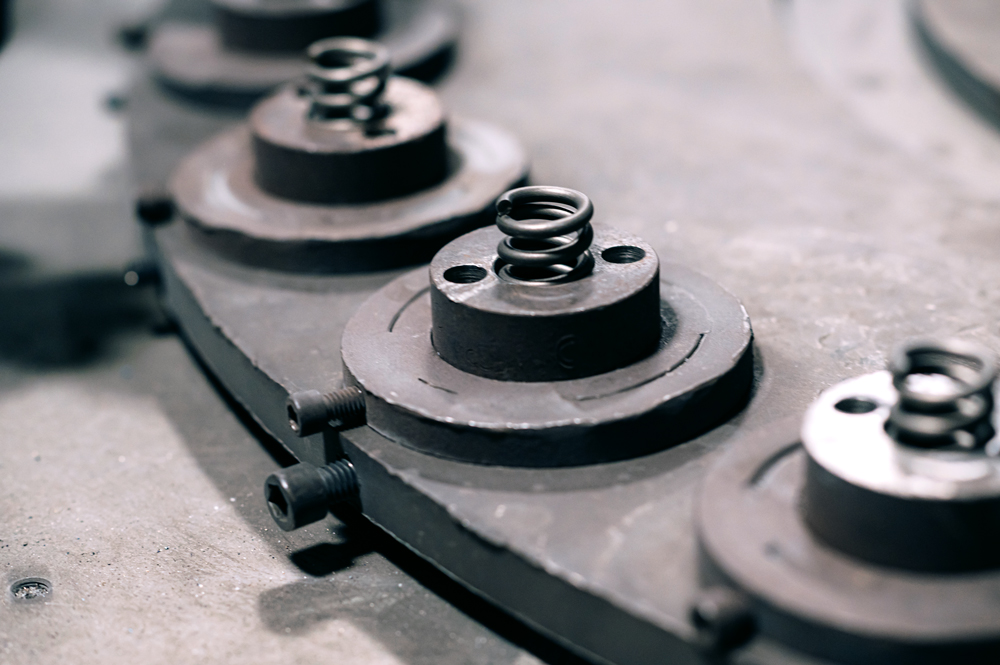

.125 stainless steel chemical industry compression springs are an open coil helical spring that offers resistance to compressive force applied axially. Compression springs are commonly coiled as a constant diameter cylinder.

About Chemical Industry Springs

Stainless steels are iron-base alloys containing 10.5% or more chromium and are engineered with good corrosion resistance, strength, and fabrication characteristics. They can readily meet a wide range of design criteria – load, service life, low maintenance, etc.

[caption id="attachment_1768" align="aligncenter" width="300"] .125 stainless steel chemical industry[/caption]

.125 stainless steel chemical industry[/caption]

When Making Your Selection, Consider Four Elements

Chemical industry springs must hold up to environmental factors.

1. Corrosion or Heat Resistance — the primary reason for specifying stainless.

2. Mechanical Properties — strength at room, elevated, or low temperature.

3. Fabrication Operations – how the product is to be made (forging, machining, forming, welding).

4. Total Cost – consider not only material and production costs, but the life cycle cost including the cost-saving benefits of a maintenance-free product having a long life expectancy.

Stainless spring wire offers high corrosion resistance properties and good tensile strength; chemical industry springs can be used in furnaces and boilers and provide a combination of corrosion resistance, weldability, and formability. Springs for the chemical industry include conical compression springs that are open-coil helical springs wound or constructed to oppose compression along the axis of wind. Helical compression springs are the most common metal spring configuration and offer resistance to linear compressing.

Contact Katy Spring Today!

Many variables characterize a corrosive environment such chemical exposure and chemical concentration, atmospheric conditions, temperature, time, etc. Therefore, it is difficult to select which alloy to use without knowing the exact nature of the environment. Our professional staff will expertly guide you through a consultation and gladly assist with your order. We offer the highest quality products at competitive prices, including compression springs, extension springs, torsion springs, die springs, and wire forms.

You can't beat our customer service. We look forward to hearing from you!

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC