Nov 1, 2019

Katy Spring manufactures lawn and garden springs, specifically the precision manufacturing of power equipment springs, metal forms, custom springs and wire forms for rapid prototyping. Many lawn and garden applications require a variety of springs, wire forms and metal stampings in their construction and operation. More examples are listed below:

battery systems

brake components

carburetor parts

clutches

engine valves

hedge trimmer motors

hitches and trailers

hose reels

irrigation

lawn mower seat shock absorption

tine rakes

trimmer spools

spark plugs

sprinklers

starter assemblies

weed wacker triggers

wheel height adjustment

Landscaping and outdoor power equipment, sprinkler heads, and air intake valves on riding lawn mowers require wire compression springs, wire extension springs, and/or wire torsion springs. Torsion springs are helical springs that exert a torque or rotary force and are subject to bending stresses. Torsion springs should always wind up from the free position and never unwind from the free position. As they wind up, torsion springs reduce in diameter while lengthening.

We offer a large stock inventory and provide engineering support and design assistance for custom springs, for instance, in case our stock of torsion springs doesn't fully meet your requirements or if you require large production quantities.

Lawn and Garden Springs

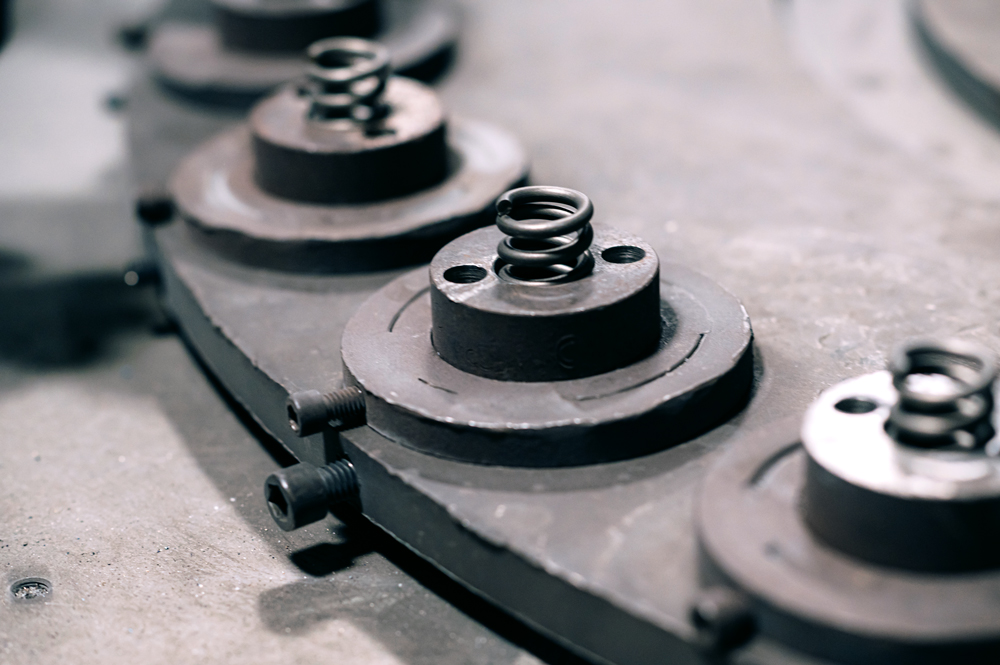

Our manufactured stock music wire torsion springs produce a torsional/rotational force and are torqued in order to produce and release energy. Torsion spring music wire for lawn and garden springs exerts a radial force rather than a linear force and is made of several material types including Music Wire ASTM A228.

We discuss dimensions with our customers such as wind direction, outer diameter, inner diameter, total coils, and rate. Components in the product include Carbon (C) and Manganese (Mn). The product itself has a higher tensile strength than stainless steel. The tensile strength of each wire diameter from each material type is different and each specific tensile strength is also taken into the equation. Music wire torsion springs are to be used in neutral environments and can be plated to resist corrosion.

[caption id="attachment_1403" align="aligncenter" width="296"] Torsion Spring Music Wire[/caption]

Torsion Spring Music Wire[/caption]

Contact Us for All Your Spring Needs

Katy Spring is a proud manufacturer of a variety of springs. You can count on on-time delivery for coiled music wire spring orders. Contact us today for a professional consultation with our expert staff.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC