Apr 12, 2022

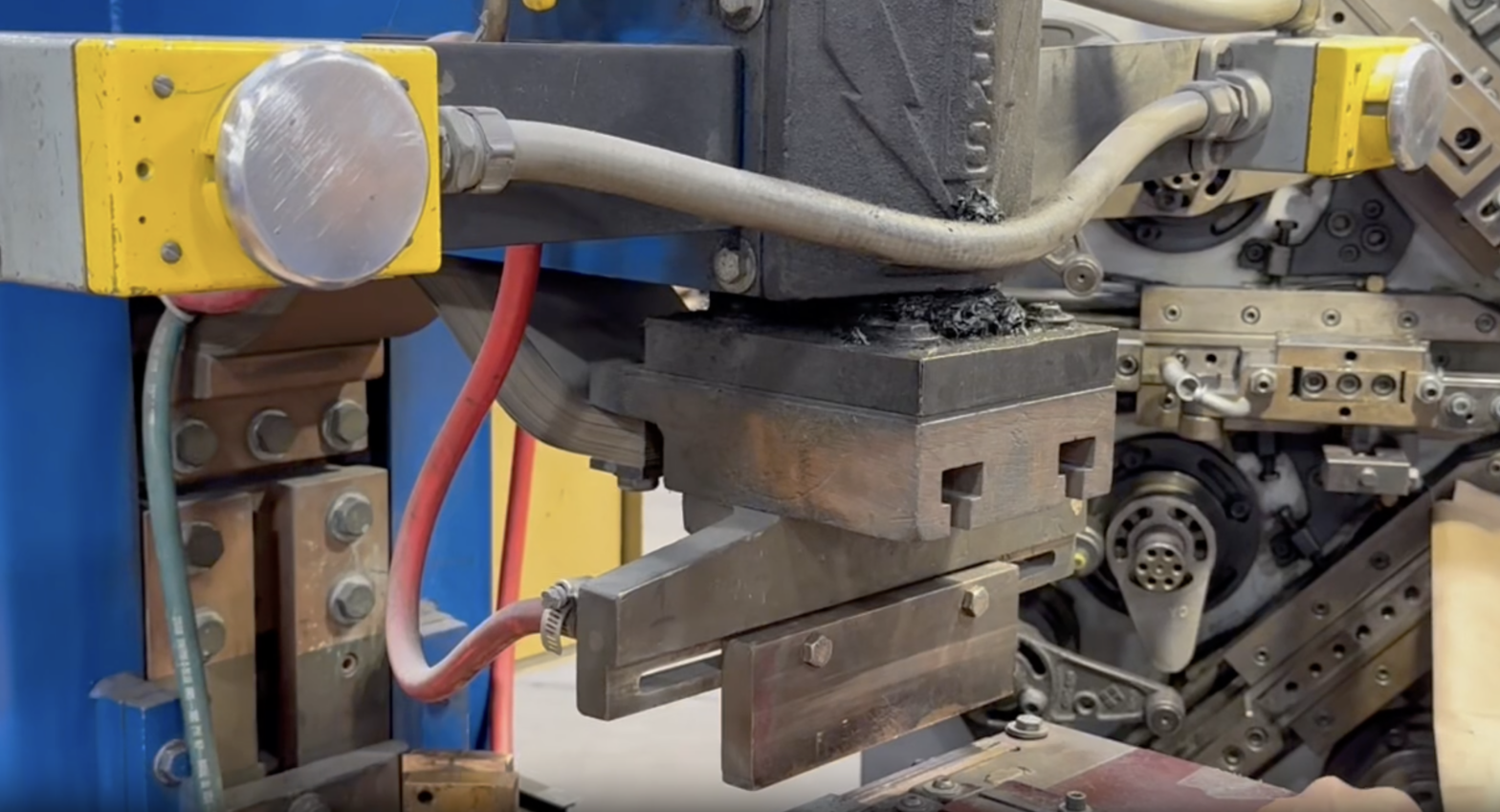

Don’t blink, you may miss it! Katy Spring’s new KHM coilers are capable of manufacturing this spring up to 40,000 parts per hour. Let me repeat that; 40,000 parts per hour! That’s 667 parts per minute and an astounding 11 springs per second….per second! The spring being manufactured here is made from .017” music wire. After coiling, the spring is stress-relieved through an inline oven at 600 degrees F for 30 minutes. Stress-relieving is a process that removes internal, residual stress from steels. The stresses are a result of the forming or in this case, coiling process. If stress is not removed from components, subtle movements could cause the parts to go out of tolerance. Do you have a spring requirement that’s within the .006” - .625” wire range? Are you having supply chain issues with materials? Call Katy Spring today for assistance: 281-391-1888 or visit our website at https://katyspring.com

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC