Jul 13, 2022

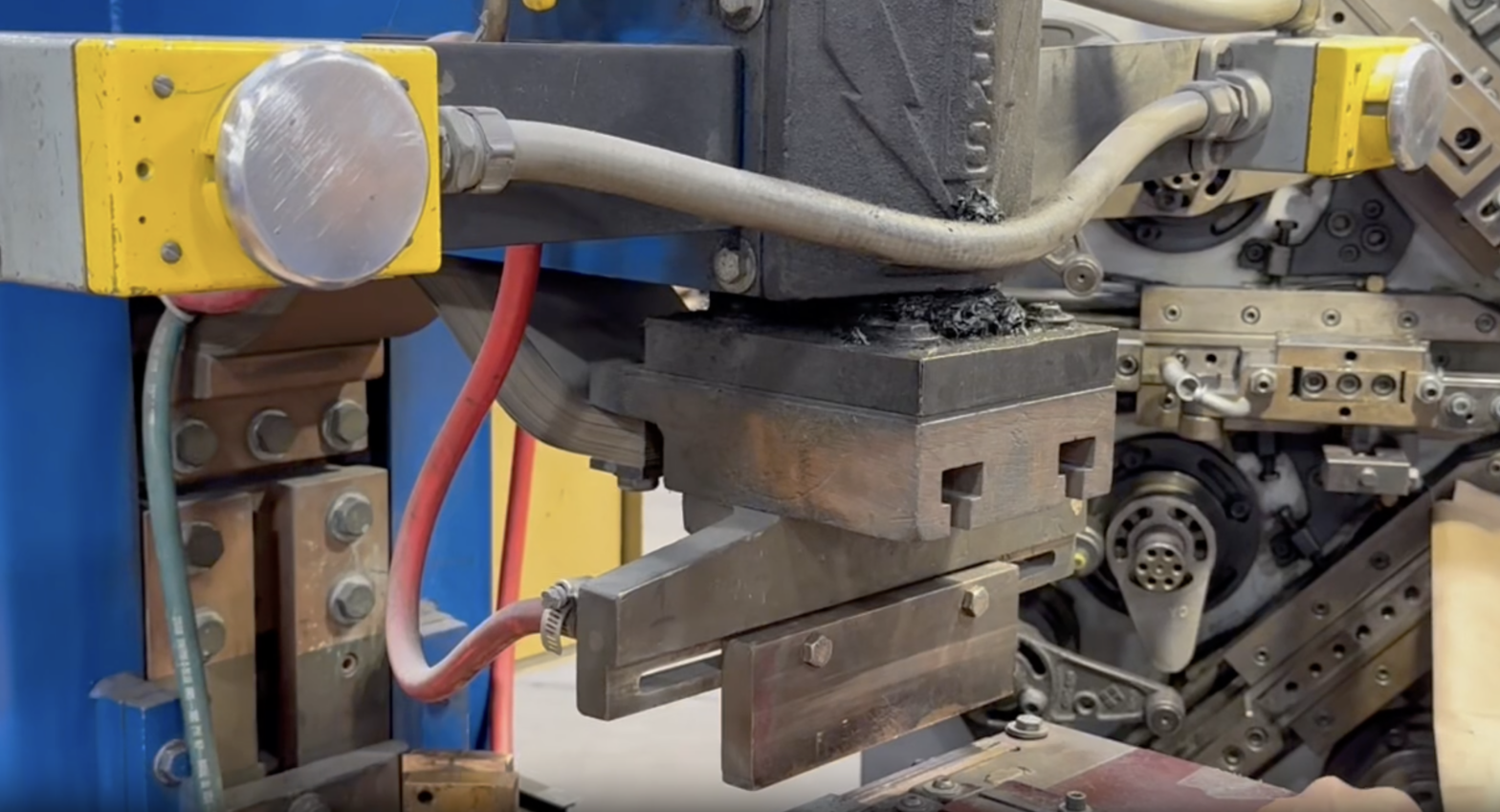

Most springs made from carbon wire are stress relieved at a temperature of 600 degrees F for a minimum of 30 minutes. Stress relieving, or “normalizing” as it’s sometimes referred to, allows the spring to relax or be relieved of stress, thereby holding its physical dimensions. Springs, by their nature, have “memory” and want to return to their original position. The heating after coiling keeps this from happening. These springs, made from .256 music wire, are being stress relieved in an in-line oven. The springs, about 10 feet in length, are placed on a conveyor which slowly transports the spring through the oven, set at 600 degrees. If the springs are too large for an in-line oven, they can be stress relieved in larger ovens that are typically loaded and unloaded with a forklift. Katy Spring can manufacture custom springs up to .625” in wire size. Contact us today to discuss your unique requirements.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC