Feb 27, 2025

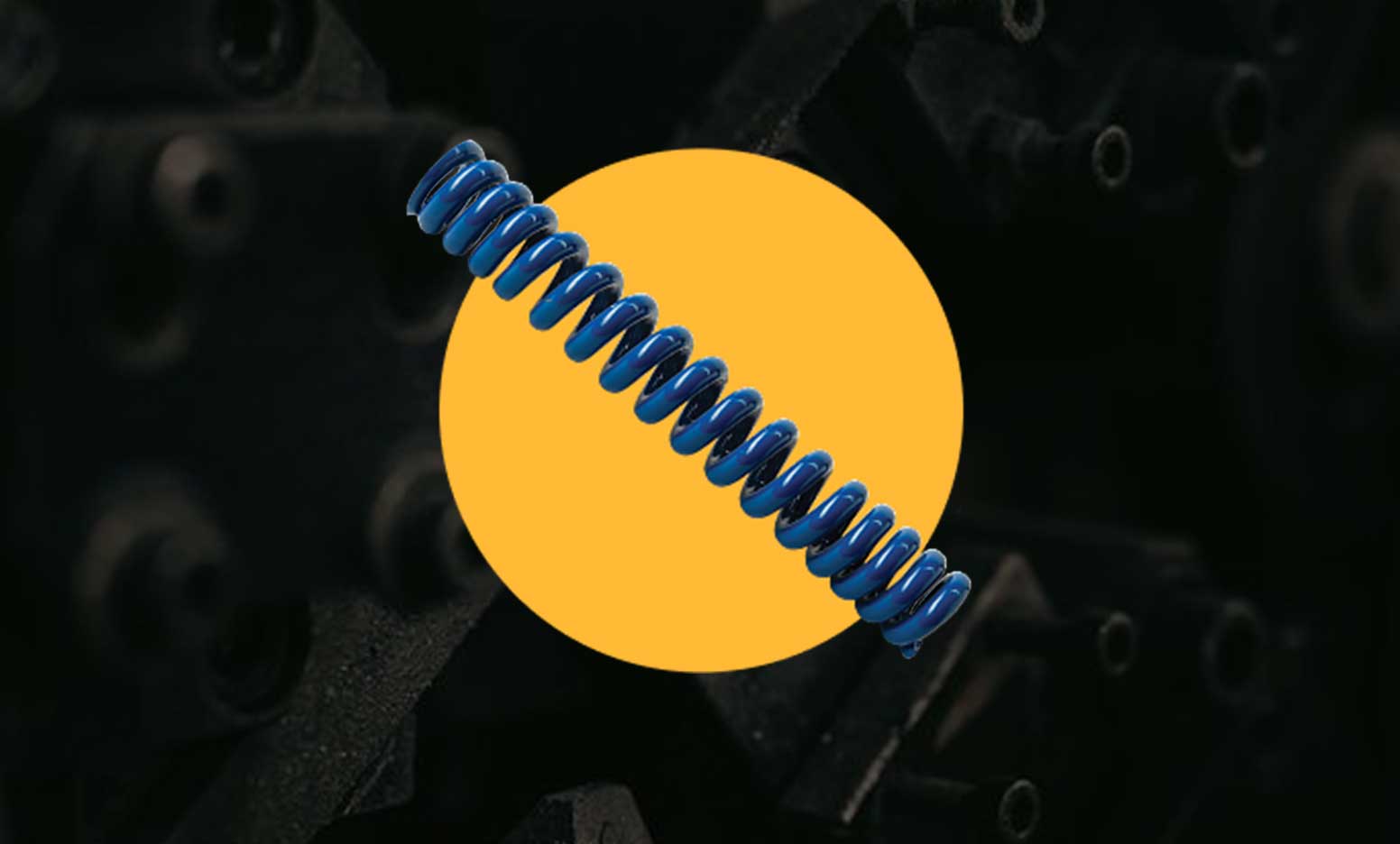

Choosing the right compression spring is critical to ensuring optimal performance in industries like automotive, aerospace, electronics, and other high-precision applications. Whether you're designing a suspension system, a landing gear mechanism, or a precision electronic switch, selecting the correct compression spring involves considering various factors such as material, dimensions, load capacity, and environmental conditions.

This guide will walk you through the essential criteria for choosing the right compression spring for your project.

1. Understand the Application Requirements

Before selecting a compression spring, it’s important to define the exact role it will play in your system. Ask yourself:

- What force is required for the spring to perform effectively?

- What space constraints exist for the spring’s dimensions?

- Will the spring undergo repetitive compression cycles?

- Does the spring need to absorb shock or maintain force over time?

2. Determine the Load and Deflection Requirements

Compression springs are designed to compress under a specific load. When choosing a spring, consider:

- Spring Rate (k): The amount of force required to compress the spring by a unit of distance.

- Maximum Load Capacity: Ensure the spring can handle the required force without permanent deformation.

- Free Length and Solid Height: The initial length of the spring and the fully compressed height.

3. Choose the Right Material

The material selection is crucial for durability and performance. Common materials include:

- Music Wire: Ideal for general applications due to its high strength and affordability.

- Stainless Steel: Resistant to corrosion, making it suitable for aerospace, marine, and medical applications.

- Inconel & Hastelloy: High-temperature and corrosion-resistant materials used in aerospace and chemical industries.

- Phosphor Bronze & Beryllium Copper: Suitable for electrical contacts due to excellent conductivity.

4. Consider the Operating Environment

Different industries require compression springs to withstand specific environmental factors:

- Automotive: Springs must resist vibration, high loads, and temperature fluctuations.

- Aerospace: Springs need to perform in extreme temperatures and high-stress conditions.

- Electronics: Small-scale precision springs are used in compact spaces and require non-corrosive materials.

- Oil & Gas: Springs must be resistant to corrosion and extreme pressures.

5. Selecting the Right Spring Design

The geometry of a compression spring affects its performance. Consider:

- End Type: Closed, open, or squared ends affect how the spring distributes force.

- Coil Pitch and Diameter: Impacts flexibility and force distribution.

- Coating & Finishing: Plating options like zinc, black oxide, or powder coating enhance longevity.

6. Prototyping and Testing

Before finalizing a spring for production, it’s crucial to test its performance in real-world conditions. Custom-engineered compression springs can be manufactured and tested to ensure:

- Proper load deflection.

- Fatigue resistance over multiple cycles.

- Compliance with industry standards (e.g., ISO 9001, AS9100 for aerospace).

7. Partner with a Trusted Spring Manufacturer

Working with an experienced spring manufacturer ensures you receive a compression spring tailored to your specifications. Katy Spring specializes in custom compression springs for automotive, aerospace, electronics, oil & gas, and other industries. Our team can help you select the best spring design for your project, ensuring durability, precision, and optimal performance.

Selecting the right compression spring requires a detailed understanding of your application’s needs, including load capacity, material selection, and environmental factors. By considering these key elements and working with a knowledgeable manufacturer, you can ensure the success of your project. Need help finding the perfect compression spring? Contact Katy Spring today for expert guidance and custom solutions!

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC