May 19, 2025

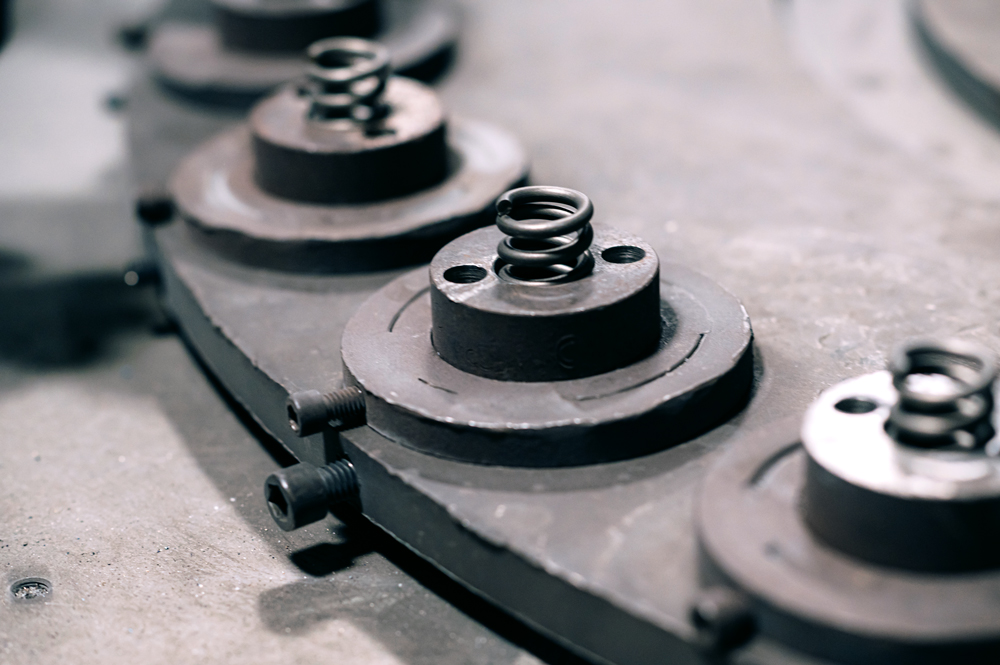

Compression springs are workhorses in countless mechanical systems—from aerospace components to automotive assemblies to consumer electronics. But when it’s time to specify a spring for your project, you’re faced with a key decision: custom or standard? While both options have their advantages, choosing the right one depends on your project’s design requirements, timeline, and budget.

Let’s break down the pros and cons of each to help you make the right choice.

Standard Compression Springs: Fast and Cost-Efficient

Standard compression springs are off-the-shelf components manufactured in common sizes, wire types, and tolerances. They’re readily available from catalogs or distributors and are ideal for:

- Prototyping and R&D

- Low-volume or one-off projects

- Applications with generous design flexibility

Pros of Standard Springs:

- Quick lead time – no waiting on custom tooling or fabrication

- Lower cost – especially at low quantities

- Easy sourcing – find them in industry catalogs or online with part numbers

Cons:

- Limited dimensions and materials

- Potential fit issues if your assembly has tight tolerances or unique specifications

- Performance trade-offs – you may have to compromise on spring rate or load

Custom Compression Springs: Designed for Precision

Custom compression springs are engineered specifically for your application’s load requirements, space constraints, environmental conditions, and cycle life expectations. They’re a must-have when:

- You need a specific spring rate, travel, or load tolerance

- Your component has tight packaging or geometry requirements

- The application involves extreme temperatures, corrosion, or fatigue

Pros of Custom Springs:

- Perfect fit and function – every dimension and property tailored to your needs

- Optimized performance – no guessing, just engineering precision

- Material flexibility – stainless, Inconel, music wire, phosphor bronze, and more

- Better lifecycle reliability – especially for high-stress or high-cycle environments

Cons:

- Longer lead times – especially if tooling or prototyping is required

- Higher initial cost – though unit pricing may level out in volume production

So, Which Should You Choose?

Here’s a quick decision guide:

| Need | Go With |

|---|---|

| Quick turnaround & low cost | Standard Spring |

| Unique space constraints | Custom Spring |

| High-performance or critical application. | Custom Spring |

| Prototyping with flexible design | Standard Spring |

| Harsh environment (heat, corrosion) | Custom Spring |

| Small run of general-purpose parts | Standard Spring |

Katy Spring Can Help

At Katy Spring, we specialize in custom compression springs designed for industries where failure is not an option. With over 25 years of experience, our team helps you engineer the perfect spring—whether you’re replacing a legacy part, upgrading performance, or building something new from the ground up.

Need help deciding between custom and standard? We’ll review your specs and application to recommend the most cost-effective solution without sacrificing quality or reliability.

GET A CUSTOM SPRING FORM

Leaders in

custom springs

With all of the ways to communicate (email, text, and fax), we still love phone calls! Call us at 281-391-1888 or contact us online. Follow us on Twitter or Facebook and keep up with the latest on industry news, changes in the raw material market, company news, and other valuable information that will assist you.

Katy Spring

Partners in Precision

Celebrating 25 years of precision

quality + precision for over 25 years.

For over two decades we have delivered quality products made to the specifications of our customers. Our customers’ success is at the forefront, meaning every details matters to Katy Spring.

we serve a wide range of industries & product types

Need a quote? It’s quick and easy, start here:

©2024 All rights reserved. Site by AC